Schluss mit Kompromissen: Warum Kundenspezifische Industrielle Scherenmesser Vorgefertigte Alternativen Übertreffen

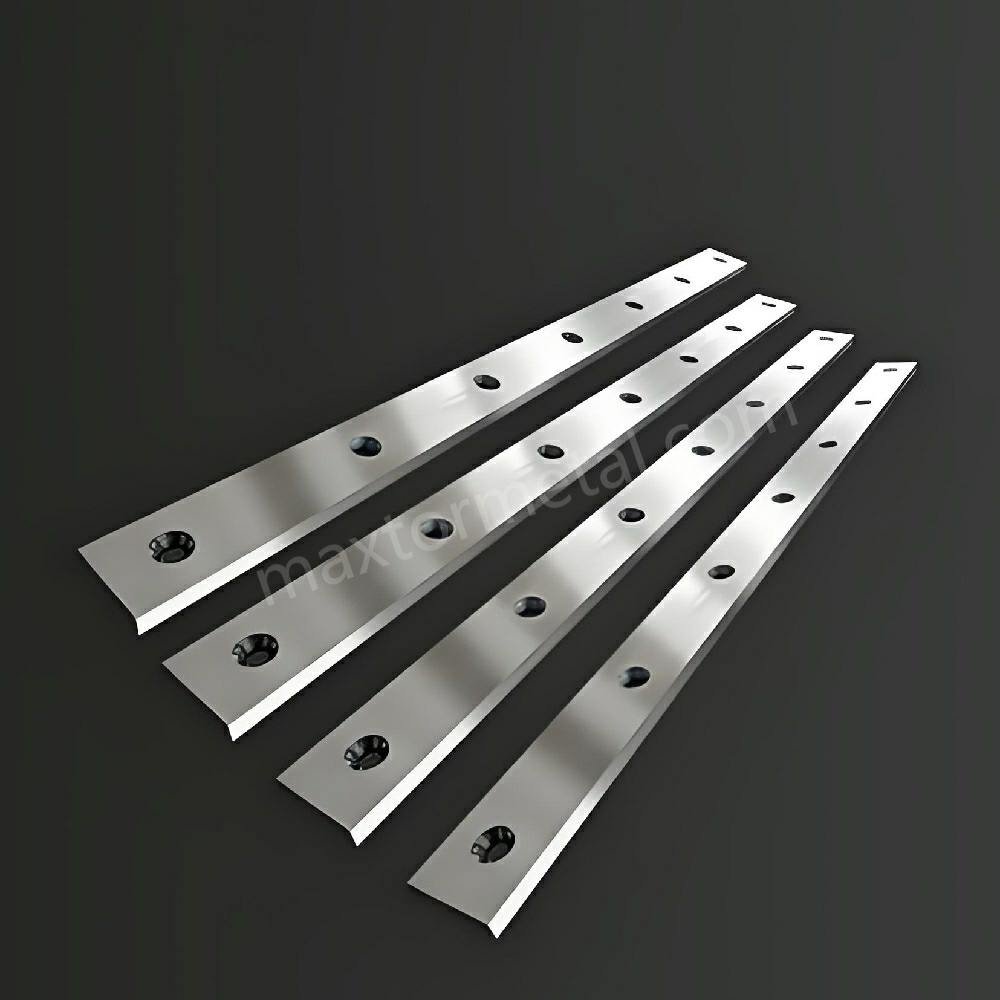

You should have cutting tools that do more than just the basics. Custom industrial shear blades are stronger and more exact than regular ones. Off-the-shelf blades cannot match their quality. Custom blades are made with special edge shapes, better materials, and skilled work. Metal Industrial’s made in usa cutting tools use custom steps to stay sharp longer. […]

Der Definitive Leitfaden für Scherenmesser für Edelstahl: Materialien und Geometrie für Hochwertige Schnitte

When you pick shear blades for stainless steel, you face special problems. Stainless steel gets hard fast and wears out tools. Galling and strong metal make cutting hard. You may see too much burring, blade wear, and bent material. Good blade material and exact shape help stop bite and tear. Metal Industrial uses new ways to […]

Analyse des Ausbrechens von Scherenmessern: Top 5 Grundursachen und Expertenstrategien zur Prävention und Reparatur

Die Analyse von Schermesserausbrüchen hilft Ihnen, die Ursachen für Messerschäden zu ermitteln. Sie zeigt auch, warum das System in Ihrem hydraulischen Schneidprozess ausfällt. Wenn Messer ermüden oder überlastet sind, brechen sie aus. Dies führt zu Zeitverlust und schlechteren Schnittergebnissen. Schäden durch mangelhafte Wartung oder Hydraulikprobleme können die Arbeit unterbrechen und Kosten verursachen. Sie sollten daher Folgendes überprüfen: […]

Jenseits der Wärmebehandlung: Erschließung Überlegener Langlebigkeit mit Kryogen Behandelten Scherenmessern

You want blades that work well and last longer in hard places. Cryogenic treated shear blades are better than regular heat-treated blades. Key Takeaways Cryogenic Treated Shear Blades: Process and Principles What Is Cryogenic Treatment Cryogenic treatment is a special way to make shear blades stronger and last longer. First, the blade gets heated to a high temperature. […]

Spezialisierte Stabscherenmesser: Präzision und Minimierung der Verformung beim Knüppelschneiden Erzielen

You need good tools to cut billets well. Bar shear blades with the right shape and material help you make clean cuts. They also help you waste less material. If you pick the right blade size and edge shape for your material, you get better results. Your blades will last longer too. Many workers have problems like bent steel, […]

OEM Scherenmesser vs. Aftermarket-Optionen: Welche Liefert die Beste TCO?

You want the best deal for your work. Picking OEM shear blades or aftermarket ones depends on your needs. It also depends on how much risk you can handle. It matters how important your job is. Total cost of ownership (TCO) means more than the price you pay. It also includes how long the blades last, the […]

Die Schnittbeherrschung: Die Kritische Rolle des Spanwinkels (Scherenmesser-Fasenwinkel) beim Industriellen Scheren

Sie werden feststellen, dass der Spanwinkel beim industriellen Scheren eine entscheidende Rolle spielt. Dieser Winkel beeinflusst die Schnittqualität, die Arbeitsgeschwindigkeit und die Standzeit des Sägeblatts. Die folgende Tabelle zeigt, wie sich unterschiedliche Spanwinkel auf die Scherkraft und die Schnittqualität auswirken: Spanwinkeltyp Auswirkung auf die Scherkraft Auswirkung auf die Schnittqualität […]

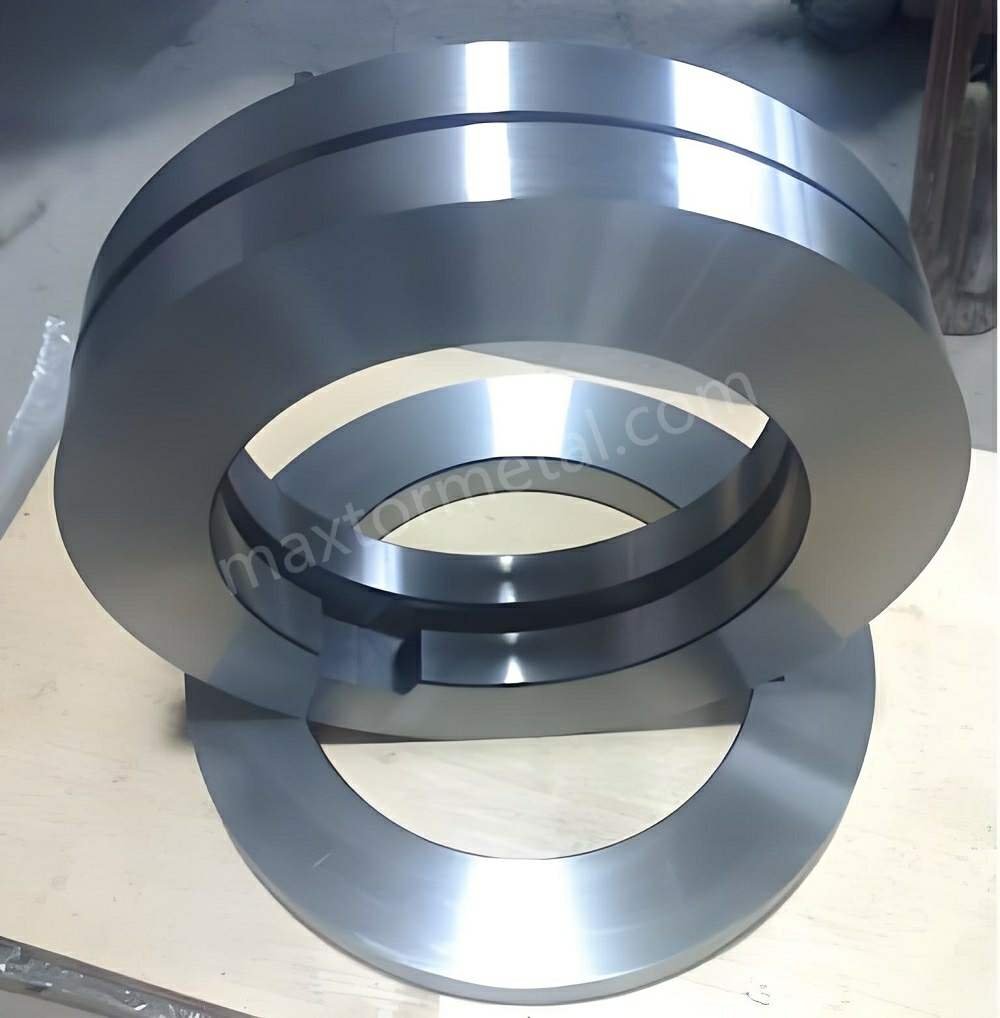

Maximale Betriebszeit: Auswahl der Besten Hochleistungs-Scherenmesser für Schrottmetall und Dickblechverarbeitung

Beim Schneiden von Schrott und dicken Blechen ist eine lange Maschinenlebensdauer wichtig. Wählen Sie robuste Schermesser, die lange halten und aus dem richtigen Stahl für Ihre Anwendung gefertigt sind. Passen Sie das Messermaterial an das zu schneidende Metall an. Entdecken Sie Schermesser mit neuen Fertigungs- und Sonderanfertigungsmöglichkeiten. Metal Industrial bietet Ihnen all diese Vorteile. […]

Warm- vs. Kaltscherenmesser: Der Definitive Leitfaden zur Materialauswahl und Temperaturgrenzen

Imagine you choose the wrong blades for a job. The blades fail quickly because you did not match the material to the heat of the metal. You need to know the right blades for hot or cold metal. Metal changes when you cut it at high or low temperatures. The right blades make a big […]

Der Ultimative Einkaufsführer für Industrielle Scherenmesser: 7 Qualitätsprüfungen vor dem Kauf

You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial […]