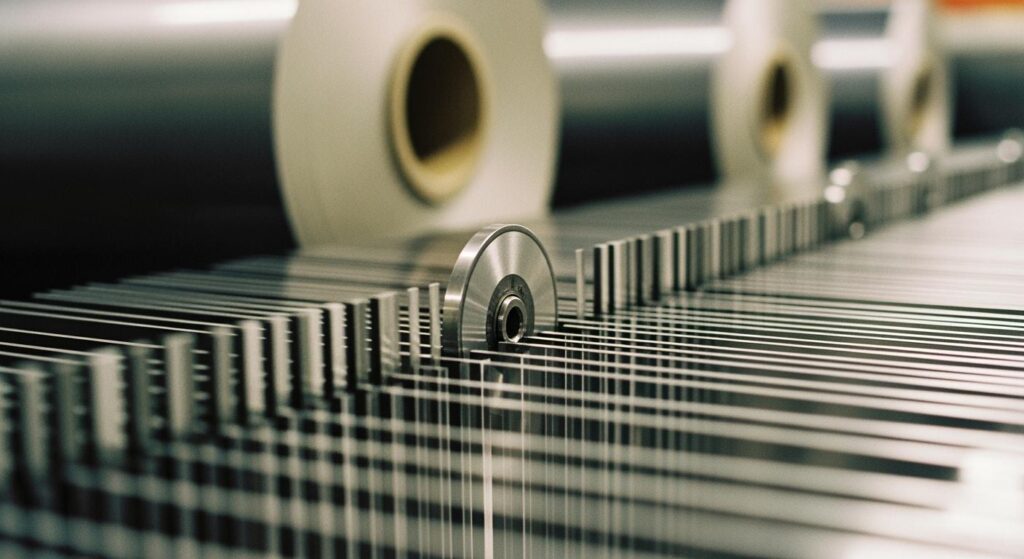

Lames de Coupe Rotatives de Haute Précision pour le Fendage de Films et de Feuilles

You use high-precision rotary slitter blade for film to achieve smooth and clean edges. These rotary slitter blade for film are essential in your operations, helping you produce neat cuts and reduce errors. Blade quality is especially important for film makers and packaging companies. Nanjing Metal Industrial specializes in manufacturing rotary slitter blade for film that meet strict […]

Les Meilleures Lames de Coupe Rotatives pour le Coupe de Métal

When you pick a rotary slitter blade for metal, you get better accuracy and strength for your work. Nanjing Metal Industrial has rotary slitter blade for metal choices that keep their sharp edge and cut well. You need a rotary slitter blade for metal that fits your metal type, how fast you work, and what size you need. […]

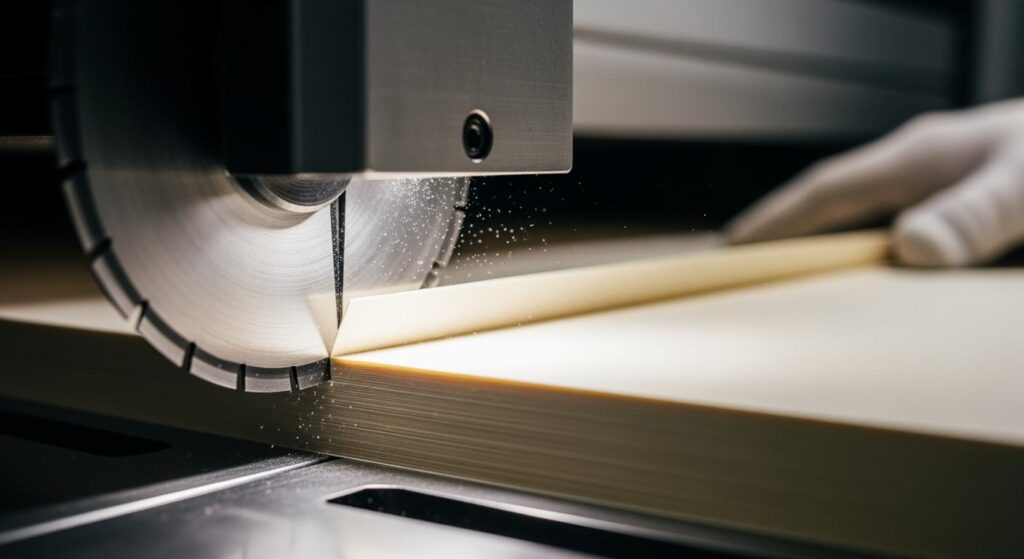

Comment Réaliser des Coupes Parfaites avec des Lames de Coupe Rotatives pour Papier

You need neat cuts when you work with paper in factories. The rotary slitter blade for paper is very important. It helps each sheet look neat and nice. The blade you pick, how you set up the machine, and how you care for your tools all matter. Watching these things helps you get the best cuts every […]

Coupe par Cisaillement vs. Coupe par Écrasement: Quelle Méthode de Coupe Est la Bonne pour Vous?

When you look at shear vs. crush slitting, you see distinct differences. Shear slitting is best for thin and delicate materials, providing clean and precise cuts. On the other hand, crush slitting works better for thick, soft, or fibrous materials. Choosing the right cutting method is crucial for achieving optimal results, as it depends on your […]

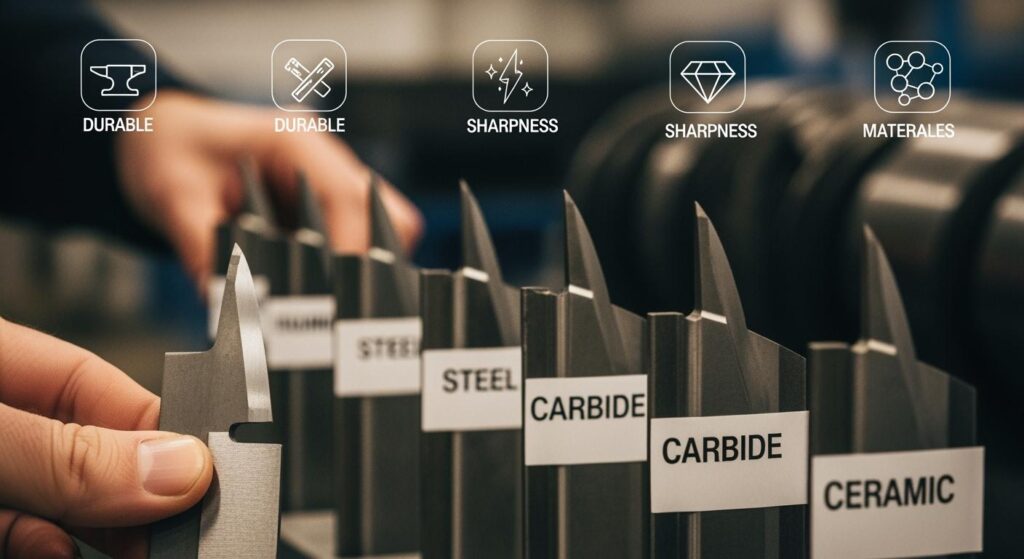

Le Guide Définitif pour Choisir le Matériau de Votre Lame de Coupe Rotative

Choosing the right rotary slitter blade material helps you get cleaner cuts and work faster. You must pick a blade material that fits your substrate and process. This choice changes how often you need to fix things and how much money you use. Key Takeaways Key Factors Slitting Process You should know how slitting works before picking […]

Le Rôle des Lames de Broyeur Textile dans le Recyclage

Textile shredder blades are very important in recycling. They cut waste textiles into small pieces. This helps people get fibers back from old clothes. Using these blades helps keep trash out of landfills. It also helps make new things from old textiles. Did you know less than 0.5% of all textile waste is recycled? Most old textiles […]

Un Plan de Maintenance Préventive pour Prolonger la Durée de Vie des Lames de Broyeur

You want your industrial shredder blades to last a long time, right? That is why you need preventative maintenance for shredder blades. Regular inspection, cleaning, and lubrication help you save money. These steps also help you avoid stopping work and keep your machines working well. When you use high-quality blades, like those from Nanjing Metal Industrial, you […]

10 Questions Essentielles à Poser Avant de Choisir un Fabricant de Lames de Broyeur

When you pick a shredder blade manufacturer, you want someone you can trust. They should have a good name for making strong and reliable products. Companies like Nanjing Metal Industrial are good examples in this field. You should check if their products work with your machines. See if they can make special options just for you. Also, find […]

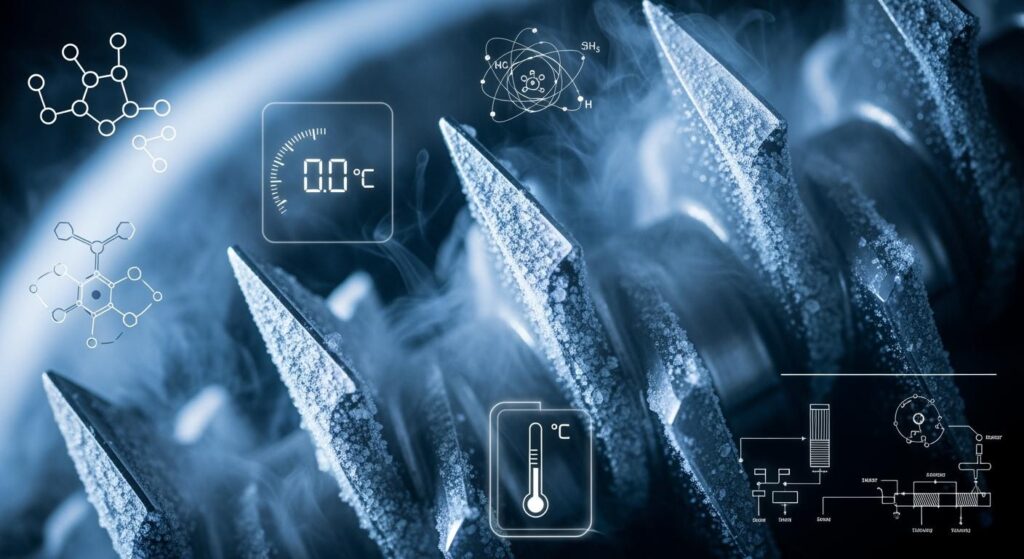

La Science Derrière les Lames de Broyeur à Traitement Cryogénique

Industrial shredders have hard work to do every day. Workers often have problems with blades that get dull fast or break easily. This causes expensive stops and many blade changes. Cryogenically treated blades help fix this problem. These blades last longer and do not wear out as fast as regular blades. Nanjing Metal Industrial is known for making […]

Précision et Efficacité avec Nos Lames de Granulateur pour Plastiques

You need to be accurate and fast when working with plastics. Granulator blades for plastic help make even pieces for recycling and molding. Good blades, smart designs, and regular care help you do your best. The table below shows how taking care of blades and using new designs helps you every day. What You Do Why It Matters […]