Tu usi lame circolari to cut big rolls into small strips in many factories. These tools are very important in metalworking, packaging, and car making. You need exact tolerances, good materials, and skilled grinding for clean cuts. Advanced companies like Nanjing Metal Industrial make Roller Shearing Blades for these needs. The world market for slitter knives will grow from $1.5 billion in 2024 to $2.5 billion by 2033. This shows why picking the best blade for your job matters a lot.

Punti chiave

- Slitter knives are important tools used in many industries. They help cut big rolls into smaller strips. These industries include steel, automotive, and packaging.

- Picking the right material for slitter knives is important. Tool steel or tungsten carbide can be used. The material you choose changes how long the knife lasts. It also affects how well it cuts.

- Keeping tight tolerances in slitting is important. It makes the cuts cleaner and creates less waste. This helps make better products.

- Checking and regrinding slitter knives often is needed. This keeps them sharp and stops problems like burrs and edge waves.

- Knowing about the grinding process is important. There is rough grinding and fine grinding. Both are needed to make good blade edges.

- Making slitter knives fit special jobs can help them work better. It can also make the blades last longer.

- Using the right oil and handling slitter knives carefully is important. This stops them from wearing out too soon. It also helps them work well.

- Watching the cutting speed and how hard the material is can help. This makes the knives last longer and cut better.

Slitter Knives in Industrial Slitting

What Are Slitter Knives?

Slitter knives cut big rolls into smaller strips. Factories use them for many jobs. You see slitter knives in machines that work with steel, paper, and plastic. There are different shapes and types of slitter knives. Some are called top knives, bottom knives, circular slitter blades, or rotary shear blades. Top knives can be flat or shaped like a dish. Bottom knives might be anvils or have grooves. When material goes between these blades, it gets sliced into strips. This helps get steel coil and other materials ready for the next step.

- Top circular slitter blades can be moved and held in place.

- Female knives are fixed to a spinning shaft.

- The material moves between the blades and gets cut.

- Shear slitting uses two rotary knives like scissors.

- The machine lines up circular blades to cut the roll into strips.

Slitter knives help you cut many kinds of materials. Steel slitting machines must be exact to make clean cuts and reduce waste.

Applicazioni chiave

Slitter knives are used in lots of industries. They help cut, trim, or slit materials to the right size. Here are some main places where slitter knives are important:

Steel Service Centers

Steel service centers use slitter knives to cut big steel coils into thin strips. This step is needed before sending steel to other factories. The equipment must be accurate so each strip is the right size and quality. Good steel slitting means better products and less scrap. This saves material and helps other factories work better.

Industria automobilistica

Car factories use slitter knives to cut steel sheets for car parts. The machine must handle strong steel and make smooth edges. This helps make safe and good cars.

Electrical & Transformer Manufacturing

Slitter knives cut electrical steel into strips for transformers and motors. The process needs tight tolerances because small mistakes can hurt performance. Good cutting tools help meet these needs.

Packaging, Rubber, and Plastics

Slitter knives cut films, labels, rubber sheets, and plastic. The knives must make clean edges and even strips. This makes packaging and plastic products look nice and work well.

Here is a table that shows more industries and how they use slitter knives:

| Industria | Applicazioni primarie |

|---|---|

| Confezione | Cutting materials for packaging, like films and labels |

| Plastics Processing | Trimming and slitting plastic films and sheets |

| Stampa | Cutting paper and special films for printing |

| Lavorazione alimentare | Slicing and dicing food like meat and vegetables |

| Paper and Pulp | Slitting and scoring paper rolls to the right size |

| Textile Manufacturing | Cutting fabric for clothes and furniture |

| Metal Industry | Cutting metal sheets or rods to exact sizes with shearing knives |

Why Tolerances, Materials, and Grinding Matter

You need to think about tolerances, materials, and grinding when picking slitter knives. These things change how well your equipment works and how long the knives last.

- Tighter tolerances mean more exact cuts, but they can cost more and waste material if not done right.

- The material you pick for slitter knives affects how long they stay sharp. Carbon steel is sharp but can rust. Stainless steel does not rust but is harder to sharpen.

- Grinding methods, like choosing the right bevel angle, help you get the best cuts for each material.

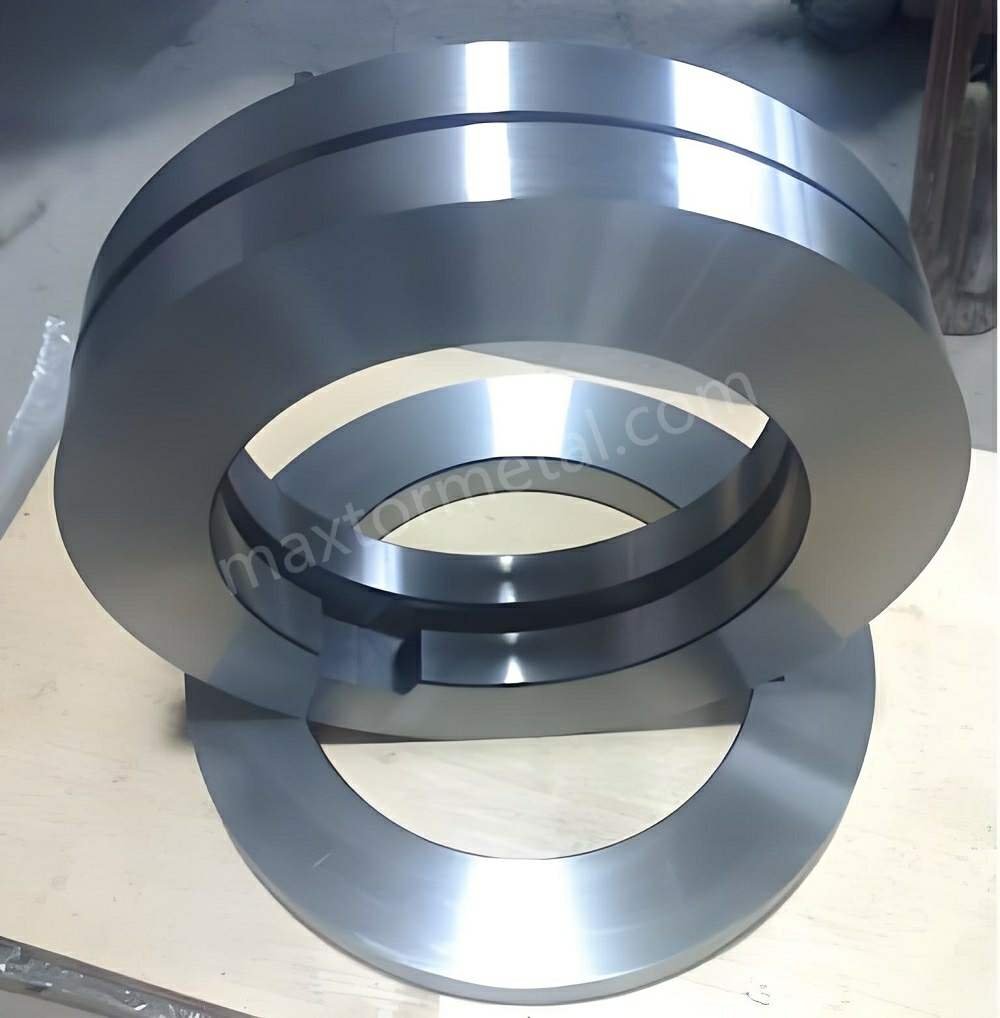

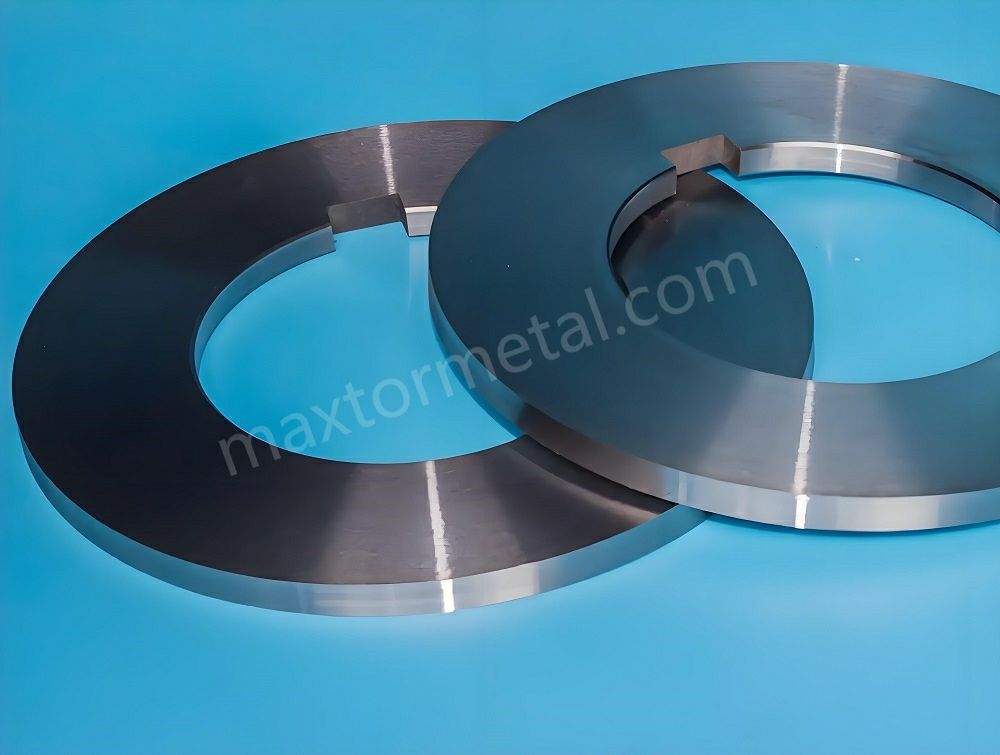

Top companies like Nanjing Metal Industrial make high-quality blades. Their Roller Shearing Blades use strong materials like high-speed steel and tungsten carbide. You can ask for custom blade shapes, materials, and surface finishes. These choices help you get the right slitter knives for your job. If you want custom blades, check their pagina delle lame personalizzate.

Using the right slitter knives and machines gives you cleaner cuts, longer blade life, and better results. This helps other factory steps work well and lets you make great products.

Steel Slitting Process: Tolerances and Quality

Understanding Tolerances

When you work with the steel slitting process, you need to pay close attention to tolerances. Tolerances tell you how much a measurement can differ from the target value. If you control tolerances well, you get better quality and fewer problems in your finished strips. Let’s look at the three main types of tolerances you should know.

Spessore

Thickness tolerance means how close the steel strip’s thickness is to what you want. If the strip is too thick or too thin, it may not fit in the next step of production. You need to check thickness often during the steel slitting process. Good thickness control helps you avoid waste and keeps your products strong.

Flatness

Flatness tolerance shows how even and smooth the steel strip is. If the strip has waves or bends, it can cause trouble in machines later. You want your strips to stay flat so they move smoothly through the slitting line. Flat strips also help you get better quality in the final product.

Parallelism

Parallelism tolerance checks if the edges of the strip stay the same distance apart from end to end. If the edges are not parallel, the strip can jam or stack unevenly. You need to keep the edges straight for high-speed slitting and to make sure every strip is the same width.

Mancia: Always measure thickness, flatness, and parallelism at different points along the strip. This helps you spot problems early and keep your steel slitting process running smoothly.

How Tolerances Affect Slitting

Tolerances play a big role in the steel slitting process. If you keep tight tolerances, you get cleaner cuts and better quality. Loose tolerances can lead to strips that are too wide or too narrow. You might also see burrs, which are sharp edges left after cutting. Burrs can make the strip unsafe and hard to use in later steps.

When you control tolerances, you also control camber, which is the curve in a strip. If the strip curves too much, it will not fit well in machines. You want to keep camber low for the best results. Burr height is another thing to watch. High burrs can slow down your process and hurt the quality of your product.

Here are some key points about tolerances in slitting:

- Steel slit tolerance tells you how much the strip can differ from the target size.

- Burr height specification helps you keep strips safe and easy to use.

- Camber control keeps strips straight and ready for the next step.

If you manage these factors well, you get higher quality and fewer problems in your steel slitting process.

Tolerance Standards and Measurement

You need to follow industry standards to make sure your slitting meets the right quality. These standards help you measure and control thickness, flatness, and other key features. Here is a table that shows some of the most common standards for the steel slitting process:

| Standard | Descrizione | Measurement Focus |

|---|---|---|

| ASTM A1008 | Covers cold-rolled sheets with specifications for thickness, width, and flatness. | Tolerances for thickness, width, flatness |

| ASTM A36 | Defines specifications for structural steel shapes, plates, and bars. | Load resistance and deformation |

| ISO 6751 | Outlines dimensions and tolerances for steel flat bars. | Uniformity in sizing |

| Certificazione ISO 9001 | Emphasizes quality management systems in the steel industry. | Consistency in quality management |

You use special tools to measure these tolerances. For thickness, you might use a micrometer or laser gauge. For flatness, you can use a straightedge or a flatness gauge. To check parallelism, you measure the distance between the edges at several points. By following these standards and using the right tools, you keep your steel slitting process accurate and your product quality high.

Nota: Always check your measurements against the standard for your industry. This helps you meet customer needs and avoid costly mistakes.

Common Issues: Burrs, Wobble, Wear

When you do steel slitting, you want every strip to be good. Sometimes, problems show up during cutting. These problems can make your strips worse and cause trouble later. You should know the most common defects, what causes them, and how they change your results.

Here is a table that lists the main defects you might see:

| Difetto | Descrizione | Primary Cause | Downstream Impact |

|---|---|---|---|

| Burr | Rough, raised edge material | Incorrect horizontal/vertical clearance | Scoring, interferes with forming |

| Edge Wave | Ripples along the strip edge | Excessive vertical clearance, stripper rings | Perpetuates into formed profiles |

| Camber | Edgewise curvature | Uneven tension/pressure, dull knives | Bow, twist, curve in formed profiles |

| Crossbow | Cross-sectional curvature, unequal lengths | Incorrect slitter setup, uneven tension | Oil canning, edge wave (in forming) |

| Poor Edge | Ragged edges, uneven fracture | Dull/damaged knives, improper clearance | Scoring, interferes with forming |

Let’s talk about these problems:

- bave: Burrs look like rough or sharp edges on the strip. Burrs happen when the space between slitter knives is not set right. Dull knives make burrs worse. Burrs can scratch other parts or make shaping hard. Check your knife setup often to keep burrs low and protect quality.

- Edge Wave: Edge wave looks like ripples on the strip’s edge. It comes from too much vertical space or problems with stripper rings. If you see edge wave, strips may not fit well in machines. This problem can stay in the final product and hurt quality.

- Camber: Camber means the strip bends sideways. You get camber when tension is not even or knives are dull. A strip with camber will not run straight in machines. This can cause jams or make the strip twist and bow later.

- Crossbow: Crossbow is a curve across the strip’s width. It happens when the slitter setup is wrong or tension is uneven. Crossbow can cause oil canning, which makes the strip look wavy. This problem also causes edge wave during forming.

- Poor Edge: Sometimes, the strip’s edge looks ragged or broken. Poor edge quality comes from damaged knives or wrong space settings. This problem can cause scoring and make it hard to shape the strip.

Mancia: You can stop many slitting problems by checking your knives, keeping them sharp, and setting spaces carefully. Regular checks help you find problems early and keep quality high.

If you want better slitting, watch for these common problems. Fixing them early helps you get better strips and smoother work. You will save time and avoid mistakes later.

Slitter Knife Materials for Steel and More

Materiali comuni

When you choose slitter knives, you need to know about the most common materials. Each type has special features that make it right for certain jobs. Here is a table to help you compare the main options:

| Materiale | Vantaggi | Svantaggi |

|---|---|---|

| Acciaio ad alto tenore di carbonio | High hardness, great wear resistance, affordable | Can be brittle, may rust |

| Acciaio inossidabile | Ottima resistenza alla corrosione, facile da lavorare | Costo più elevato |

| Acciaio per utensili | Exceptional hardness, high wear resistance, works at high heat | Costly, harder to process |

| Carburo di tungsteno | Resistenza all'usura estremamente elevata, lunga durata | Fragile, costoso |

Acciaio per utensili

You often use tool steel for slitter knives in the steel industry. Tool steel gives you a mix of strength, toughness, and wear resistance. This material keeps its shape and sharpness even when you cut hard or thick steel. Tool steel works well in high-temperature jobs, so you can use it for heavy-duty slitting. You may find it a bit harder to process, but it pays off with long-lasting performance.

Acciaio ad alta velocità

High-speed steel stands out for its toughness. You can use it when you need a knife that can handle sudden shocks or impacts. This material keeps its hardness up to 500°C. You get good wear resistance and a blade that does not chip easily. High-speed steel is a smart choice for slitting softer steel or when you need to run your machines at high speeds.

Carburo di tungsteno

Tungsten carbide is one of the hardest materials you can pick for slitter knives. It gives you extreme wear resistance and keeps its edge even at very high temperatures, up to 1000°C. You should use tungsten carbide when you cut thick steel, rubber, or tough composites. The main trade-off is that it can be brittle and costs more, but you get a blade that lasts much longer.

Leghe speciali

Specialty alloys combine different metals to balance hardness and toughness. You can use these alloys for many cutting jobs. They work well when you need a knife that can handle both hard and soft steel. Specialty alloys give you flexibility and can be tailored for your specific needs.

Material Properties and Selection

When you pick slitter knife materials, you need to look at key properties. These features decide how well your knife will work and how long it will last.

Hardness and Toughness

Hardness means how well a knife resists wear and keeps its edge. Toughness shows how much impact or stress the knife can take before it breaks. You want a balance between these two. A harder knife lasts longer but may chip if it is too brittle. A tougher knife can handle shocks but may wear out faster. For example, tungsten carbide gives you the highest hardness, while high-speed steel offers more toughness. The best knife for you depends on your job and the type of steel you cut.

Mancia: Always match the hardness and toughness of your knife to your cutting needs. This helps you get the best performance and longest life from your slitter knives.

Wear and Corrosion Resistance

Wear resistance helps your knife last longer when you cut abrasive steel or other tough materials. Corrosion resistance is important if you work in wet or chemical environments. Stainless steel gives you great protection against rust. Tungsten carbide and tool steel offer top wear resistance. You should think about your work setting and pick the right material for your needs.

Here is a list of key properties to consider:

- Hardness: Keeps the edge sharp and resists wear.

- Toughness: Absorbs shocks and prevents chipping.

- Edge Retention: Stays sharp over time, so you do not need to change knives often.

- Corrosion Resistance: Stops rust in wet or harsh places.

- Wear Resistance: Handles abrasive steel and extends blade life.

If you need help choosing, you can visit the custom blades page for expert advice on material selection and customization.

Industry-Specific Recommendations

You need to match your slitter knife materials to your industry. Each field has its own demands and best choices.

Steel Mills and Heavy Engineering

Steel mills need knives that can handle thick coils and tough jobs. Tool steel and tungsten carbide are top picks here. These materials give you the strength and wear resistance needed for heavy-duty slitting. You get clean cuts and long blade life, even in high-speed steel processing lines.

New Energy and Electronics

In electronics and new energy, you often cut thin steel or special alloys. Stainless steel works well because it resists rust and keeps a sharp edge. M2 high-speed steel is also a good choice for high-volume jobs. You get durability and precision, which are key for making small, accurate parts.

Automotive and Appliances

Automotive factories use slitter knives to cut steel sheets for car bodies and appliances. D2 high carbon steel gives you extra hardness and edge retention. Stainless steel is also popular for its rust resistance and cost-effectiveness. You want a knife that can handle both soft and hard steel, so you get smooth edges and reliable parts.

Customization and Surface Treatments

You can make slitter knives work better by picking the right custom options and surface treatments. Every cutting job is unique. Sometimes, you need a blade that fits your machine exactly. Other times, you need one for special materials. Customization helps you get the blade that matches your needs.

- You can choose the blade’s size, shape, and edge style for your machine and material.

- You can pick the steel or alloy that lasts longer and cuts cleaner.

- You can ask for coatings like titanium or ceramic to make the blade stronger.

Surface treatments help slitter knives last longer. Coatings such as titanium and ceramic put a hard layer on the blade. This layer helps the knife fight wear and lowers friction. When you cut tough or sticky stuff, these coatings keep the edge sharp for more cuts. Some coatings also protect the blade from heat and small scratches. This is important for fast or heavy jobs.

Customization means more than just changing a blade’s size. You work with engineers to design a slitter knife for your process. This teamwork helps you get more machine time, better products, and lower costs.

Here is a table that shows how different surface treatments help slitter knives:

| Trattamento della superficie | Main Benefit | Il migliore per |

|---|---|---|

| Titanium Coating | Elevata resistenza all'usura | High-speed steel slitting |

| Rivestimento ceramico | Low friction, heat control | Cutting sticky or abrasive materials |

| Nitrurazione | Surface hardness | General-purpose steel slitting |

| cromatura | Resistenza alla corrosione | Wet or chemical environments |

If you pick the right custom options and surface treatment, your slitter knives last longer and work better. You change blades less often and make better products. If you have a special job or tough material, talk to your blade supplier about custom choices. The right options can really help your cutting process.

Shear Slitting: Grinding and Edge Quality

Grinding Process Overview

Shear slitting depends on the quality of your blade edges. You need to understand how the grinding process shapes the performance of your slitter knives. Each step in grinding changes how well your knives cut and how long they last.

Rough and Fine Grinding

You start with rough grinding. This step removes most of the extra material from the blade. You use coarse grains to shape the edge quickly. The surface feels rough after this step, but it gets the blade ready for the next stage.

Next, you move to fine grinding. Here, you use finer grains to smooth the edge. This step removes only a small amount of material. You get a sharp, clean edge that is free from burrs. Fine grinding makes sure your slitter knives can cut cleanly and last longer.

Here is a table that shows the main steps and their effects on edge quality:

| Fare un passo | Descrizione | Effect on Edge Quality |

|---|---|---|

| Roughing | Initial stock removal using coarse grains | Produces a rougher surface, prepares for finishing |

| Finitura | Minimal material removal with fine grains | Achieves a smooth surface and sharp, burr-free edge |

You should always check the edge after each grinding step. A good edge means better results in the shear slitting process.

Mirror Polishing

Mirror polishing is the final touch in preparing your slitter knives. You use very fine abrasives to polish the edge until it shines. This step removes tiny scratches and makes the edge even smoother. A mirror-polished edge reduces friction during slitting. You get cleaner cuts and less heat build-up. This helps your knives last longer and keeps your products looking good.

Advanced Grinding Techniques

You can use advanced grinding techniques to get even better results in shear slitting. These methods use modern machines and technology to make your blades sharper and more precise.

Superfinishing

Superfinishing takes the edge to the next level. You use special machines to polish the blade with extreme accuracy. This process removes the last bits of roughness from the edge. You get a surface that is almost perfectly smooth. Superfinishing helps your slitter knives cut with less force. You see fewer defects and less waste in your slitting line.

- CNC grinding and polishing make your blades sharper and smoother.

- CNC machines control the shape and polish of the edge with high precision.

- These techniques give you uniform edges, which means every cut is clean.

- You get less waste when cutting rubber, plastic, or thin steel.

If you want the best results in shear slitting, consider using superfinishing and CNC technology.

Avoiding Thermal Cracks

Thermal cracks can ruin your slitter knives. These cracks happen when the blade gets too hot during grinding. You need to control the temperature to protect the edge. Use coolants and take breaks during grinding to keep the blade cool. If you avoid thermal cracks, your knives stay strong and last longer.

- Always use enough coolant during grinding.

- Do not rush the process; let the blade cool between steps.

- Check for signs of heat damage before using the knife in shear slitting.

Edge Geometry and Performance

The shape of your blade edge, or edge geometry, is key to how well you can do shear slitting. You need to pick the right edge profile and cutting angle for your job.

Profilo del bordo

The edge profile is the shape of the blade’s cutting edge. You can choose a straight, rounded, or beveled profile. Each shape works best for different materials and slitting speeds.

- Blade geometry affects how fast and clean you can cut.

- The right edge profile gives you better product quality.

- A good edge radius makes your blade last longer and cut more precisely.

- You save money by reducing how often you need to change blades.

You should match the edge profile to your material and slitting needs for the best results.

Angolo di taglio

The cutting angle is the angle at which the blade meets the material. This angle changes how sharp the blade is and how much force you need to cut.

- The cutting edge angle is important for sharpness and cutting force.

- A sharper angle makes cutting easier but can wear out faster.

- A more obtuse angle gives the blade more strength and lasts longer.

- The right angle helps you balance between easy cutting and blade life.

You should test different angles to find what works best for your shear slitting process. The right geometry and angle help you get clean cuts, reduce waste, and keep your knives working longer.

Remember, the edge geometry and cutting angle are just as important as the material and grinding steps. Good choices here make your shear slitting line more efficient and cost-effective.

Impact on Knife Longevity

You want your slitter knives to last as long as possible. The way you handle grinding and edge geometry in shear slitting has a big effect on knife longevity. When you use the right grinding process, you help your knives stay sharp and strong. If you skip steps or use poor grinding, your knives wear out faster. Shear slitting puts a lot of stress on the blade edge. You need to understand how each part of the process affects the life of your knives.

When you set up your shear slitting line, you should focus on three main things:

- Qualità del bordo

A sharp, smooth edge cuts cleaner and lasts longer. If you use rough grinding, you remove more material but leave the edge uneven. Fine grinding and mirror polishing make the edge smooth. This reduces friction during shear slitting. Less friction means less heat and slower wear. You get more cuts before you need to regrind or replace the knife. - Geometria del bordo

The shape and angle of the edge matter in shear slitting. A thin, sharp angle cuts easily but can chip if the material is hard. A thicker angle is stronger but may need more force to cut. You need to match the edge geometry to your material and speed. If you get this right, your knives last longer and you get better results from your shear slitting process. - Grinding Consistency

Every time you regrind a knife, you change its shape a little. If you use different grinding angles or skip polishing, you shorten the knife’s life. You should use the same grinding process each time. This keeps the edge strong and helps you get the same results in every shear slitting job.

Mancia: Always inspect your knives after grinding. Look for cracks, chips, or uneven edges. These problems can cause early failure in shear slitting.

How Shear Slitting Conditions Affect Knife Life

Shear slitting is a demanding process. You run machines at high speeds and cut tough materials. If you use the wrong knife or poor grinding, you see more wear and need to change blades often. Here are some factors that affect knife longevity in shear slitting:

- Durezza del materiale: Harder materials wear down the edge faster. You need a knife with the right hardness and toughness for your job.

- Velocità di taglio: High speeds create more heat. Heat can soften the edge and cause cracks. Use coolants and control speed to protect your knives.

- Blade Alignment: Poor alignment causes uneven wear. Always check that your knives line up before starting shear slitting.

- Regrind Quality: Each time you regrind, you remove some material. If you grind too much, the knife gets weak. If you grind too little, the edge stays dull. Find the right balance for your shear slitting needs.

Maintenance and Equipment Condition

You need to keep your shear slitting equipment in good shape. Dull or damaged knives hurt your process and lower knife life. Clean your machines and check for loose parts. Lubricate moving parts to reduce friction. Replace worn-out parts before they cause bigger problems.

Here is a simple checklist for longer knife life in shear slitting:

- Inspect knives before and after each use.

- Use the same grinding and polishing steps every time.

- Keep your machines clean and well-oiled.

- Store knives in a dry, safe place.

- Train your team to spot early signs of wear.

| Fattore | Effect on Knife Longevity | What You Should Do |

|---|---|---|

| Qualità del bordo | Higher quality = longer life | Use fine grinding and polishing |

| Geometria del bordo | Correct angle = less chipping | Match geometry to material |

| Grinding Consistency | Consistent process = reliable edge | Standardize grinding steps |

| Equipment Condition | Good shape = less wear | Maintain and clean machines |

| Regrind Quality | Proper regrind = stronger knife | Remove just enough material |

Remember, every step you take in shear slitting affects how long your knives last. Good habits save you money and keep your production running smoothly.

Shear slitting is not just about making cuts. It is about making sure your knives work well for as long as possible. When you pay attention to grinding, edge geometry, and maintenance, you get more value from every knife. You also get better results in your shear slitting line. If you want to improve knife longevity, start with these best practices and keep learning as you go.

Practical Tips for Slitter Knives

Picking, caring for, and fixing slitter knives can really help your work. If you do things the right way, you get better products, less machine stoppage, and save money. Here are some easy tips to help you do well with steel cutting and slitting.

Guida alla selezione

Matching Tolerances to Application

You need to match tolerances to your job. Every job needs something different. If you cut steel, watch thickness, flatness, and parallelism. These things change how your slitting works and how your strips look.

- Keep tension steady while you cut. This stops problems and keeps steel strong.

- Know your steel’s properties. Tensile strength and elasticity help you pick the best knife and settings.

- Always check thickness and width before you start. This stops waste and helps you work faster.

When you match tolerances, you get cleaner cuts and fewer problems. This makes your products better and saves you money.

Choosing Materials and Geometry

Picking the right blade material and edge shape is important. Think about what steel you cut, how fast you work, and how long you want your knives to last.

- Pick blade material for how long you need it and what you cut. For tough steel, use tool steel or tungsten carbide.

- Check the anvil’s hardness. It costs more to replace, so protect it by picking the right knife.

- Set the nip point right. This helps knives last longer and wear less.

- Choose the best edge shape and angle for your steel. Sharper angles cut easier but wear out faster. Thicker angles last longer but need more force.

If you have a special job, you can talk to companies like Nanjing Metal Industrial. Their engineers help you pick the best materials and designs.

Migliori pratiche di manutenzione

Inspection and Regrinding

Check and regrind your slitter knives often to keep them sharp and safe. Look for wear, notches, or bent spots before you use them. Make a schedule for checking knives based on how much you use them and what you cut.

| Industria | Tipo di lama | Durata media della lama |

|---|---|---|

| Taglio Metal | Acciaio rapido (HSS) | 50–100 ore |

| Lavorazione alimentare | Acciaio inossidabile | 100–150 ore |

| Taglio di carta e pellicola | Con punta in carburo | 80.000–100.000 tagli |

| Industria tessile | Lame da taglio rotanti | 60–120 ore |

- Clean knives after each use to stop dirt.

- Regrind blades when they get dull or damaged. This keeps cuts clean and safe.

- Use the same grinding steps every time to keep the edge strong.

Lubrication and Handling

Lubrication and careful handling help slitter knives last longer. Oil moving parts to lower friction and stop rust. Always handle knives gently to avoid chips or cracks.

- Oil knife holders and moving parts often.

- Use the right coil tools to stop damage when feeding.

- Store knives in a dry, safe place when not using them.

- Keep machines clean and check for loose parts.

Doing these things keeps your knives working well and lowers machine stoppage.

Troubleshooting Slitting Problems

Out-of-Tolerance Cuts

If your cuts are not the right size, you may have alignment or setup problems. Bad cuts slow you down and waste steel.

- Check blade alignment before you start.

- Make sure knives match the thickness and width you need.

- Change machine settings if strips are too wide or narrow.

Burrs and Edge Defects

Burrs and rough edges hurt product quality and can be unsafe. These problems often come from dull blades or wrong knife spacing.

| Tipo di problema | Sintomi | Possibili cause | Soluzioni |

|---|---|---|---|

| Burrs on Slit Edges | Rough, jagged, or sharp edges on slit strips. | Blade Dullness, Incorrect Clearance, Blade Alignment Issues | Sharpen or Replace Dull Blades, Adjust Knife Clearance, Ensure Proper Blade Alignment |

| Knife Breakage or Premature Wear | Frequent blade breakage, Rapid knife dulling. | Excessive Cutting Pressure, Incorrect Blade Hardness, Poor Material Alignment | Optimize Cutting Pressure, Select the Right Blade Material, Ensure Proper Coil Feeding and Alignment |

- Sharpen or change dull blades quickly.

- Adjust knife spacing for your steel and slitting needs.

- Make sure blades are lined up and set right.

Premature Wear

If knives wear out too fast, you may need to change cutting pressure or pick a better blade material. Bad alignment and wrong feeding also cause early wear.

- Lower cutting pressure if knives wear fast.

- Pick a blade with the right hardness for your steel.

- Feed coils smoothly and keep them lined up.

If you keep having trouble, you can ask experts at Nanjing Metal Industrial for help. They give special solutions and support for tough slitting jobs. Many customers have made their process better and saved money by working with skilled engineers.

Tip: Regular care, smart choices, and quick fixes help you get the most from your slitter knives. These steps keep your steel slitting running well and make your products better.

You help slitter knives work well by watching tolerances, materials, and grinding. Knife design decides how exact your cuts are. The material you pick makes knives last longer and need less fixing. Grinding and the angle of the edge change how well the knife cuts.

To make your slitting better:

- Pick the best machines and cutting tools for your job.

- Change cutting speeds when needed and keep tools in good shape.

- Check your knives often so you waste less material.

If you pay close attention to picking and caring for knives, you stop machine problems and save money. For special help or advice, talk to skilled engineers or contatta il nostro team di vendita.

Domande frequenti

What are slitter knives used for?

You use slitter knives to cut large rolls of material into smaller strips. These knives work in steel mills, packaging plants, and many other industries. They help you get the right size and shape for your products.

How do you choose the right material for slitter knives?

You pick the material based on what you need to cut. Tool steel works for hard metals. High-speed steel handles fast jobs. Tungsten carbide lasts longer with tough materials. Always match the knife to your application.

Why do tolerances matter in slitting?

Tolerances control how close your cuts are to the target size. Tight tolerances give you cleaner strips and less waste. If you ignore tolerances, you may get uneven or unusable strips.

How often should you regrind slitter knives?

You should regrind slitter knives when you see dull edges or poor cuts. Regular inspection helps you decide. Frequent regrinding keeps your knives sharp and your cuts clean.

What causes burrs on slit edges?

Burrs form when knives are dull or not set up right. Incorrect knife clearance also leads to burrs. You can reduce burrs by sharpening knives and adjusting the setup.

Can you use slitter knives for materials other than steel?

Yes, you can use slitter knives for paper, plastic, rubber, and textiles. You need to choose the right blade material and edge geometry for each type of material.

How do you maintain slitter knives for longer life?

You clean and inspect knives after each use. Store them in a dry place. Lubricate moving parts. Regrind blades when needed. Good care helps your slitter knives last longer.

What is the difference between top and bottom slitter knives?

Top slitter knives usually move and cut from above. Bottom knives stay fixed and support the cut. Both work together to slice material into strips.

Vedi anche

Lame Circolari per Taglio Longitudinale

Cosa Sono le Lame per Cesoia Rotante e Come Funzionano?

Esplorazione delle applicazioni delle lame da taglio Metal nella produzione

Come selezionare la lama a rullo giusta per le tue esigenze

Lame per Taglierina Rotativa Aftermarket vs. OEM: Un'Analisi Costi-Benefici