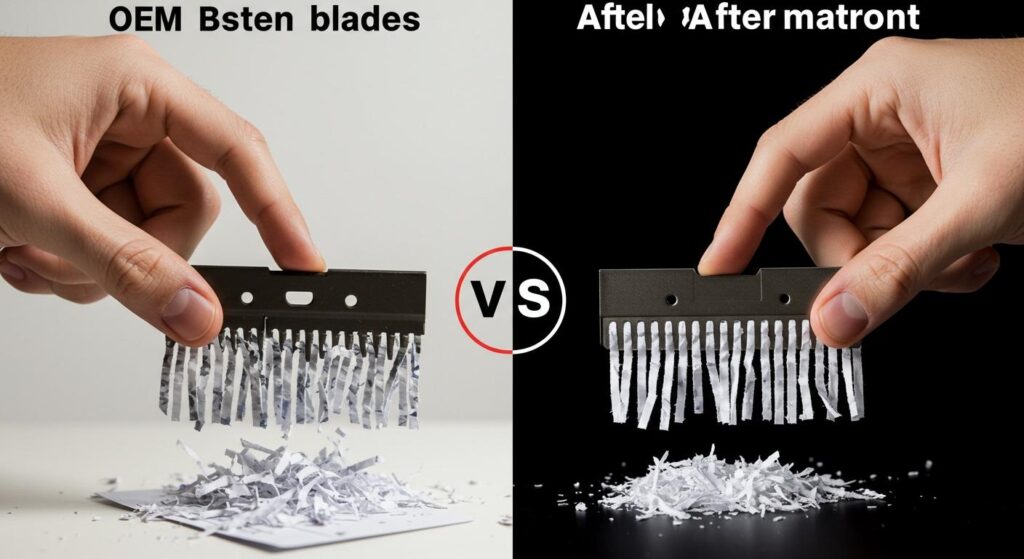

OEM シュレッダーブレード vs. アフターマーケットシュレッダーブレード:比較と選択

OEMシュレッダーブレードとアフターマーケットシュレッダーブレードを比較する際は、シュレッダーに最適なブレードを選びたいものです。多くの人は、OEMシュレッダーブレードの方が品質が良く、刃先が鋭く、動作の信頼性が高いと考えています。最適な選択は、お客様のニーズによって異なります。以下の点にご留意ください。Nanjing Metalは、お客様のニーズに合ったOEMシュレッダーブレードを販売しています。特に、最高品質で長持ちするブレードをお求めの場合は、ぜひご検討ください。重要なポイント OEMシュレッダーブレードの定義 OEMシュレッダーブレードとは、お客様のシュレッダー専用に作られたブレードのことです。これらのブレードは、OEM(オリジナル機器メーカー)から供給されます。お客様のシュレッダーに完璧にフィットし、すべてのパーツと連携して動作します。OEMシュレッダーブレードは[…]

スムーズな運用のためのシュレッダーブレードのトラブルシューティングガイド

You want your shredder to work well. You also want to avoid expensive problems. Shredder blade troubleshooting helps you find issues early. It lets you fix them quickly. Regular checks and care make shredders work better. They also help shredders last longer. Key Aspect Impact on Shredder Lifespan and Efficiency Regular Maintenance Makes shredders last longer and stops breakdowns. Routine Inspections Finds problems before big failures happen. Blade Maintenance Keeps blades cutting well and lowers motor stress. Staff Training Stops damage from mistakes during use. Environmental Control Lowers wear from dust, wetness, and temperature changes. Key Takeaways Recognizing the Top 3 Signs of Industrial Shredder Blade Failure When you use an industrial […]

原料鋼から精度まで:シュレッダーブレードの製造プロセス

You watch raw steel change into a strong shredder blade through the meticulous shredder blade manufacturing process. This process begins with selecting the right material. Then, skilled workers shape the steel, heat it, and finish it. Each step—design, forming, hardening, polishing, and quality checking—enhances the blade’s strength and longevity. Suppliers utilize these steps to ensure shredders operate efficiently. Nanjing Metal allows customers to customize their needs and conducts thorough quality checks, making its blades exceptional. Key Takeaways Material Selection Picking the right material is the first step. It is very important in making shredder blades. You must choose steel that fits your shredding job. The steel you pick affects how long the blade […]

タイヤシュレッダーブレードがリサイクル成功に与える影響を発見

When you recycle tires, tire shredder blades are very important. The right blades help your work go faster and smoother. They also give you cleaner results and can save you money. New technology, like dual-shaft and quad-shaft systems, has made things better for many places. Look at how these different technologies compare: Technology Type Impact on Efficiency Cost Savings Dual-shaft and quad-shaft More tires shredded, uses less energy Costs less to run AI-driven optimization Changes for different tires and sizes Less waste, more good results You might want to check your blades now. Upgrading them could help your work a lot. Key Takeaways Tire Shredder Blades and Recycling Efficiency Tire shredders are […]

スクラップメタル破砕およびリサイクルのための最高のヘビーデューティーシュレッダーブレード

You need heavy duty shredder blades to make recycling metal safe and fast. Brands like Nanjing Metal Industrial and Fordura make strong blades that last a long time. It is important that blades are tough, resist wearing out, and fit your machines well when you shred lots of metal. Good materials, smart blade shapes, and taking care of the blades help stop problems and save money. The world market for shredder blades is getting bigger. In 2023, it was worth over $447 million because more companies want better ways to handle waste and must follow stricter recycling rules. Key Takeaways Heavy Duty Shredder Blades Selection Picking the right heavy duty shredder blades helps your shredder work […]

カスタムシュレッダーブレードがあなたのビジネスにとって賢明な投資である理由

Are you tired of spending a lot on repairs and losing time at work? Custom shredder blades are a smart choice. They help your machines work better and keep things safe. Picking the right blade for your material makes less waste. It also helps your business make more money. New ways to make and change blades fit what you need. Many companies save real money: Nanjing Metal Industrial has blades you can change to fit your needs and help you do well. Key Takeaways Standard Blades vs. Custom Shredder Blades Common Issues with Standard Blades Standard blades in your metal shredder can cause many problems. These problems slow down your work and cost […]

2025年版 販売中の産業用シュレッダーブレード購入ガイド

Choosing the right industrial shredder blades for sale can seem challenging. You want blades that fit your machine, match your material, and come from a reliable supplier. The global market for these blades will reach about USD 363.89 million in 2025, showing steady growth. This growth means you have more options than ever, so making the right choice matters for your business. Key Takeaways Industrial Shredder Blades for Sale Overview When you look for industrial shredder blades for sale, you need to know the main types, materials, and uses. This overview helps you compare choices and see what top brands like Nanjing Metal Industrial have. Blade Types Different shredders use different blade types for many materials. […]

初心者とプロのためのシュレッダーブレード交換ガイド

You can change shredder blades by following some easy steps. First, turn off the machine. Next, use the correct tools. Always follow your manufacturer’s instructions. Safety is very important. If you use high-quality blades your shredder works better. The blades also last longer. Here are some quick benefits: This shredder blade replacement guide helps you stay safe. It also helps your shredder work well. Key Takeaways When to Replace Blades Knowing when to swap out your shredder blades keeps your machine running smoothly. If you wait too long, you might face jams, poor shredding, or even damage to your shredder. Let’s break down the signs you should watch for. Signs of Wear […]

刃の寿命を延ばす:シュレッダー刃の研ぎ方ガイド

Yes, you can make Nanjing Metal Industrial shredder blades last longer by sharpening shredder blades with a safe, step-by-step process. When you keep your blades sharp, they last longer and you spend less money on new ones. You also get better results when shredding things like plastic, paper, rubber, metal, and wood. One company switched to high-performance blades and saw a 20% increase in efficiency and a 15% decrease in energy use. This helped them save money and have less downtime. Key Takeaways Blade Dullness Signs Performance Issues Reduced efficiency Your shredder blades may start working slower. The machine might need more time to finish the same job. You may have to push harder or run […]

高性能木材シュレッダーナイフで木材廃棄物収益を最大化する

Upgrade to high-performance wood shredder knives to make more money from wood waste. New shredding technology breaks down wood fast. It makes less waste and lowers storage costs. You can fit more wood in each load. This saves fuel and labor. Shredding also makes it easier to move and handle wood. This helps your business run better and make more money. Key Takeaways Wood Waste Processing and Revenue Value of Wood in Biomass Markets Wood waste can be useful and worth money. Many companies use wood waste for biomass fuel and wood chips. These things help make energy and help landscaping and farming. The market for biomass fuel and wood chips gets bigger […]