タングステンカーバイドナイフの研磨とメンテナンス方法

タングステンカーバイド製のナイフの研ぎとお手入れは難しい場合があります。この素材は摩耗しにくいですが、注意しないと欠けてしまうことがあります。刃を熱しすぎると、小さなひび割れが生じることがあります。タングステンカーバイドよりも柔らかい研磨剤を使用すると、刃が損傷する可能性があります。タングステンカーバイド製のナイフを効果的にメンテナンスするには、チゼルエッジを45°に一定に保つことで、摩耗の偏りを防ぐことができます。ダイヤモンドグラインダーまたは目の細かい砥石が必要です。軽い力で研ぎ、ほこりが付かないように注意してください。この方法により、タングステンカーバイド製のナイフを安全に保ち、最適な状態で使用できます。重要なポイント タングステンカーバイドブレード:ツールと安全性 ダイヤモンドグラインダー ダイヤモンドグラインダーは、タングステンカーバイドブレードの研ぎに最適です。 […]

タングステンカーバイドナイフが欠ける理由 — 一般的な故障モードとそれらを回避する方法

タングステンカーバイドナイフは、使い方を間違えたり、強い衝撃を与えたりすると欠けてしまうことがあります。これらのナイフは非常に硬いため、長期間鋭い切れ味を保ちます。しかし、使用時には注意が必要です。Metal工業用タングステンカーバイドナイフは、工場で非常に頑丈に使用されています。多くの人が、これらのナイフは通常の鋼製ナイフよりもはるかに長持ちすると言っています。ナイフを正しく使用し、正しくセットアップすれば、欠けを防ぎ、刃を長持ちさせることができます。重要なポイント:タングステンカーバイドナイフが欠ける理由工場でタングステンカーバイドナイフを使用する場合、長持ちさせたいものです。これらのナイフは硬いことで知られています[…]

工業用ブレードにおける炭化タングステン vs. 鋼:性能、摩耗、コスト

When you compare tungsten carbide vs steel blades, you notice significant differences. Tungsten carbide blades are much harder and do not wear out quickly. They maintain their sharpness even under high temperatures. On the other hand, steel blades are better at absorbing hits and shocks. Initially, steel is less expensive. The table below highlights these main differences: Property Tungsten Carbide Steel Hardness Extremely high (8.5–9 Mohs) Lower (4–8 Mohs, depending on grade) Wear Resistance Excellent Good, but wears faster Heat Resistance Very high Moderate Corrosion Resistance High Varies Toughness Moderate High Machinability Difficult Easy Cost Higher Lower Choose the blade that best suits your needs. Consider how long you want the edge […]

アフターマーケット製 vs. OEMロータリースリッターブレード:費用対効果分析

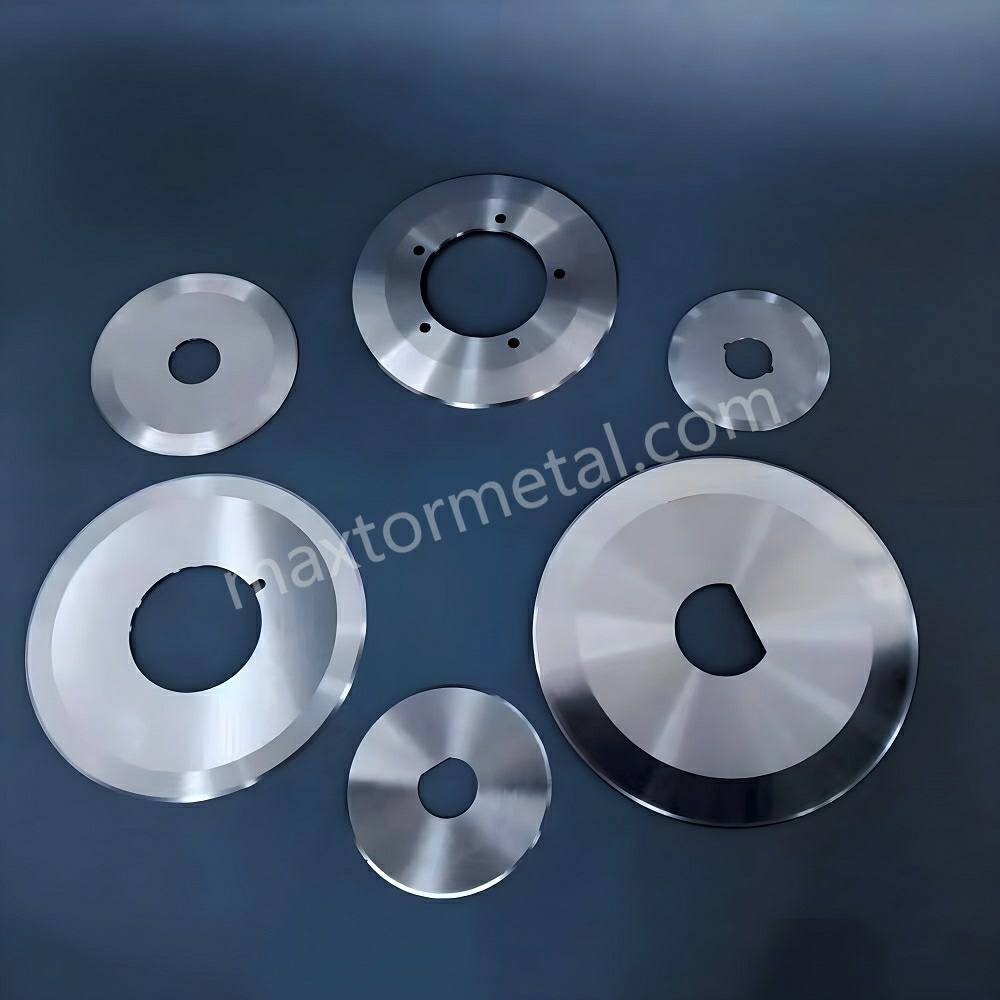

You want blades that give you good value. Many people pick OEM rotary slitter blades. These blades have high quality. They last a long time. They work well and do not break easily. When you choose blades, you think about cost. You should also consider how long they will last. Check how often they need fixing. Consider what materials you will be cutting. You check how hard the blade is. Finally, you check that the blade fits your machine. Nanjing Metal Industrial cares about quality. They help you get blades that fit your needs. Key Takeaways Cost Comparison: OEM vs. Aftermarket Slitting Blades Picking OEM rotary slitter blades or aftermarket blades changes your […]

精度と耐久性:ゴム・プラスチック切断用ロータリースリッターブレード

You use rotary slitter blades for rubber and plastic to make accurate and strong cuts. Good blades help you get cleaner cuts and last longer. This is true when you pick blades that fit your needs. Companies like Nanjing Metal Industrial have many choices. They focus on making blades that work well for you. The table below shows how these features help your work go faster and better: Feature Description Durability Good imported materials help the blades last a long time. Clean and Accurate Cuts Special CNC machines make sure cuts are exact and smooth. Versatile Performance These blades work with many machines and tools. Cost-Effective Strong blades save you money because you replace […]

ロータリースリッターブレードの寿命を延ばす 5 つの実証済み方法

You want your rotary slitter blades to last a long time and extend rotary slitter blade life. By keeping your blades sharp, you save money while also experiencing less downtime and improved product quality. For instance, using high-speed steel or carbide-tipped blades significantly contributes to this goal. These blades can enhance your productivity by making you work 20% faster, while also helping your rotary slitter blades last longer. Refer to the table below for quick facts about saving money: Cost Saving Aspect Description Potential Savings Fewer Blade Replacements Blades last longer, so you buy fewer new ones. $10 to $1000+ per blade Reduced Downtime Less fixing means machines stop less often. […]

ロータリースリッターナイフサプライヤーを選ぶ際に考慮すべき 10 の主要な要因

Choosing the right rotary slitter knife supplier can change your cutting results. You need slitting tools that work well and give steady quality. A good supplier with smart manufacturing and helpful service can lower downtime and make your results better. Key Takeaways Blade Quality Standards Precision and Consistency You want slitting knives that work the same every time. Precision is important for every job. If blades cut accurately, your products look good and work well. Consistency means each roll gets a high-quality cut. Check if the supplier uses advanced ways to make blades. These ways help keep blades sharp and strong. Nanjing Metal Industrial tests and checks every slitter blade. They look at size, […]

テープ用ロータリースリッターブレード:粘着性の問題を断ち切る

You use rotary slitter blades for tape to cut sticky materials. These blades help you handle tough sticky problems. Sticky problems can slow down how fast you work. If you pick good blades, you get cleaner cuts. Cleaner cuts mean you waste less tape. Blades made from tungsten carbide and high-speed steel last longer. These materials also help blades work better. You can change blade features to fit your needs. Some companies buy better blades for their work. These companies work up to 20% faster. They also have fewer stops in production. Key Takeaways Rotary Slitter Blades for Tape and Adhesives What Are Rotary Slitter Blades Rotary slitter blades cut big rolls […]

高精度ロータリースリッターブレードがあなたのオペレーションにとって極めて重要である理由

You need high precision rotary slitter blades for your work. These blades help your machines run well and not break down. Sharp and balanced rotary slitter blades make clean cuts. They also help you use less material and waste less. This tool cuts wide rolls into smaller pieces with exact sizes. It helps you keep your products good and your work fast. Good blade shapes give you smooth edges with no rough spots. You do not need extra work to fix the edges, so you save money. Custom slitter blades made from strong materials help you get good results every time. Key Takeaways Precision and Consistency with High Precision Rotary Slitter Blades Uniform Cutting […]

ロータリースリッターブレードの交換:ステップバイステップガイド

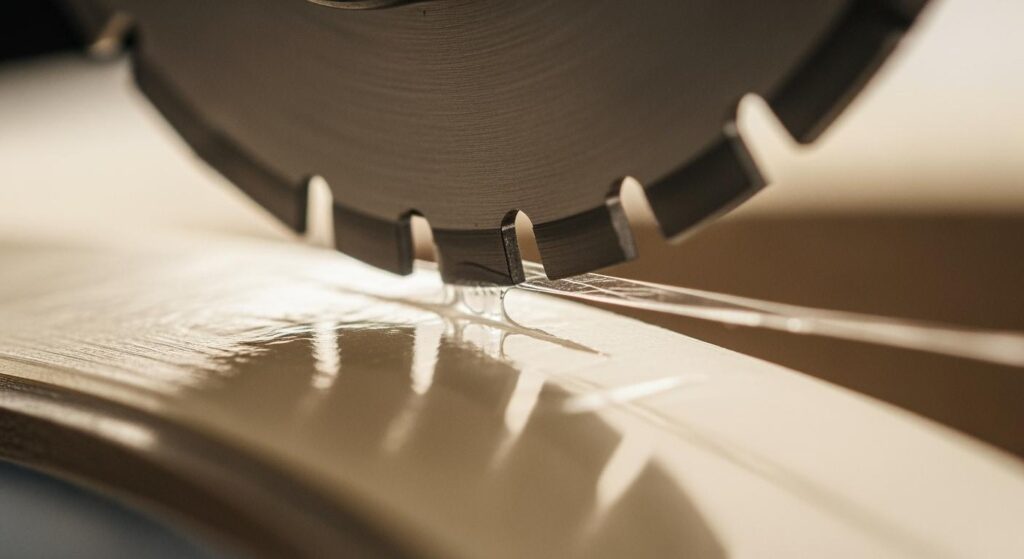

If you do not perform a rotary slitter blade replacement the right way, you can lose time making products. About 25% of machine downtime occurs because tools break, such as blades. Good blades help you cut better and waste less. These blades also enhance workplace safety by reducing accident risks. There are many blade types and custom options available for different jobs and materials. If you take care of your blades regularly, your work remains efficient and safe. Key Takeaways Tools and Safety for Rotary Slitter Blade Replacement You must get ready before changing a rotary slitter blade. You need the right tools and safety gear. Picking the correct blade is also […]