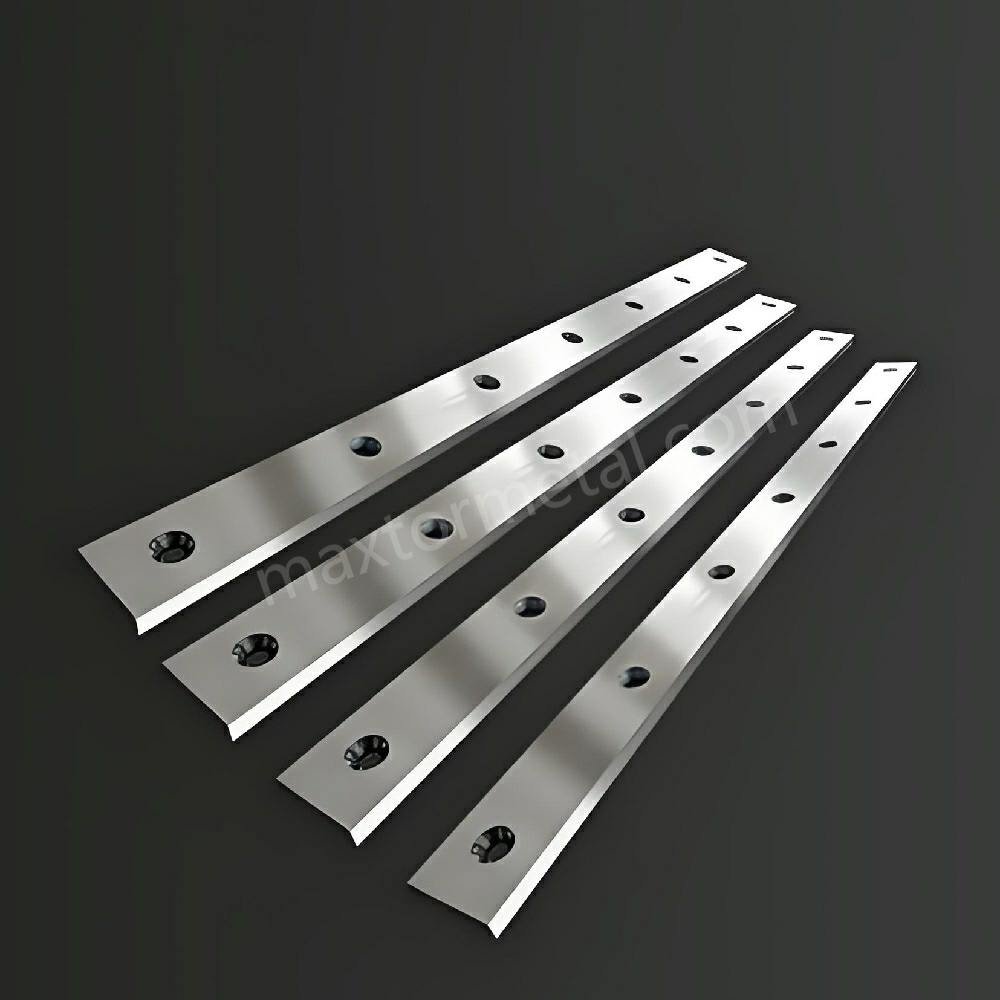

Pare de Comprometer: Por Que as Lâminas de Tesoura Industriais Personalizadas Superam as Alternativas Prontas para Uso

You should have cutting tools that do more than just the basics. Custom industrial shear blades are stronger and more exact than regular ones. Off-the-shelf blades cannot match their quality. Custom blades are made with special edge shapes, better materials, and skilled work. Metal Industrial’s made in usa cutting tools use custom steps to stay sharp longer. […]

O Guia Definitivo para Lâminas de Tesoura para Aço Inoxidável: Materiais e Geometria para Cortes de Alta Qualidade

When you pick shear blades for stainless steel, you face special problems. Stainless steel gets hard fast and wears out tools. Galling and strong metal make cutting hard. You may see too much burring, blade wear, and bent material. Good blade material and exact shape help stop bite and tear. Metal Industrial uses new ways to […]

Análise de Lascamento de Lâminas de Tesoura: As 5 Principais Causas Raiz e Estratégias Especialistas para Prevenção e Reparo

Shear blade chipping analysis helps you find why blades get damaged. It also shows why the system fails in your hydraulic cutting process. When blades get tired or stressed, they chip. This makes you lose time and good cuts. Damage from bad maintenance or hydraulic problems can stop work and cost money. You need to check […]

Além do Tratamento Térmico: Desbloqueando Longevidade Superior com Lâminas de Tesoura Tratadas Criogenicamente

You want blades that work well and last longer in hard places. Cryogenic treated shear blades are better than regular heat-treated blades. Key Takeaways Cryogenic Treated Shear Blades: Process and Principles What Is Cryogenic Treatment Cryogenic treatment is a special way to make shear blades stronger and last longer. First, the blade gets heated to a high temperature. […]

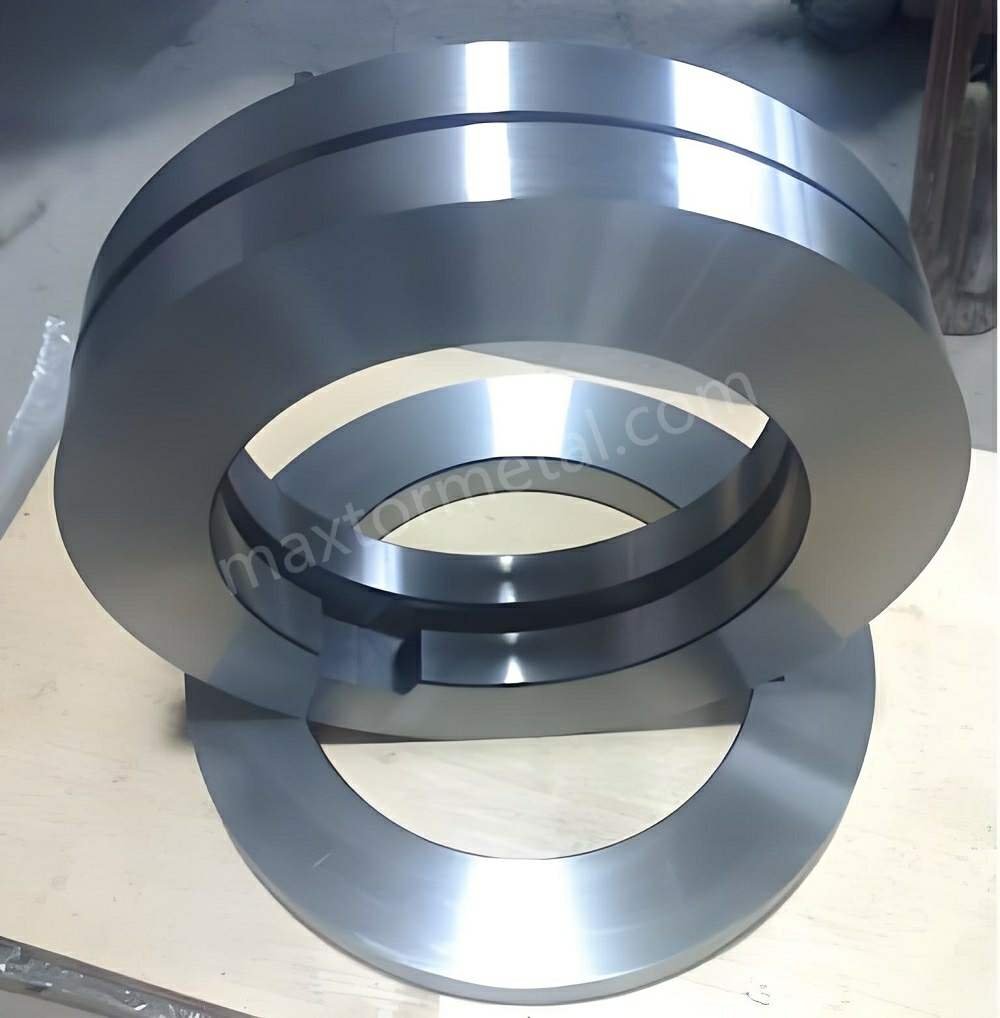

Lâminas de Tesoura de Barra Especializadas: Alcançando Precisão e Minimizando a Distorção no Corte de Tarugos

You need good tools to cut billets well. Bar shear blades with the right shape and material help you make clean cuts. They also help you waste less material. If you pick the right blade size and edge shape for your material, you get better results. Your blades will last longer too. Many workers have problems like bent steel, […]

Lâminas de Tesoura OEM vs. Opções de Pós-venda: Qual Oferece o Melhor TCO?

You want the best deal for your work. Picking OEM shear blades or aftermarket ones depends on your needs. It also depends on how much risk you can handle. It matters how important your job is. Total cost of ownership (TCO) means more than the price you pay. It also includes how long the blades last, the […]

Dominando o Corte: O Papel Crítico do Ângulo de Ataque (Ângulo de Bisel da Lâmina de Tesoura) no Cisalhamento Industrial

You will see that the rake angle is very important in industrial shearing. This angle changes how well you cut, how fast you work, and how long your blade lasts. The table below shows how different rake angles change shearing force and cut quality: Rake Angle Type Effect on Shearing Force Effect on Cut Quality […]

Maximize o Tempo de Atividade: Escolher as Melhores Lâminas de Tesoura para Serviço Pesado para Sucata e Processamento de Chapas Grossas

You want to keep machines working for a long time when cutting scrap metal and thick plates. Pick heavy duty shear blades that last long and have the right steel for your job. Match the blade material to the metal you cut. Find shear blades with new manufacturing and custom choices. Metal Industrial gives you these features. […]

Lâminas de Tesoura a Quente vs. a Frio: O Guia Definitivo para Seleção de Materiais e Limites de Temperatura

Imagine you choose the wrong blades for a job. The blades fail quickly because you did not match the material to the heat of the metal. You need to know the right blades for hot or cold metal. Metal changes when you cut it at high or low temperatures. The right blades make a big […]

O Guia Definitivo do Comprador para Lâminas de Tesoura Industriais: 7 Checagens de Qualidade Antes de Comprar

You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial […]