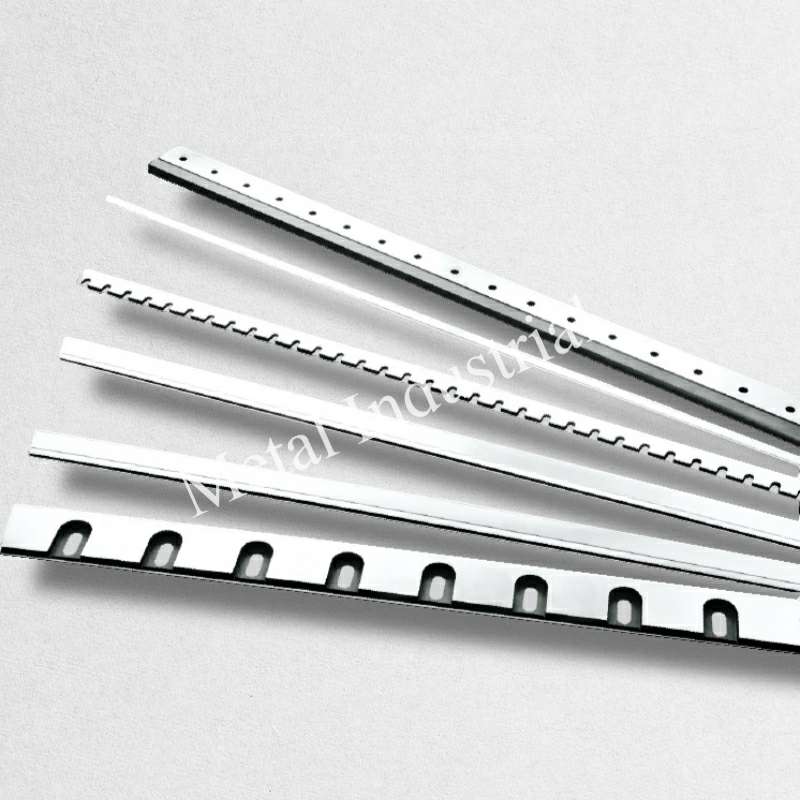

Le Guide d'Achat Ultime pour les Lames de Cisaille Industrielles : 7 Contrôles de Qualité Avant d'Acheter

You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial […]

Affûter les Lames de Cisaille Comme un Pro : Éviter les Erreurs de Meulage Courantes et Étendre le TCO

You get great results when you sharpen shear blades. Keep the blade shape correct and use the right angle. Keep the blade’s original shape. Take off only a little bit of material. Metal Industrial Shear Blades have special edge design and strong materials. Careful sharpening helps them cut better and last longer. Use the right way […]

Le Guide Définitif pour le Réglage du Jeu des Lames de Cisaille : Formules, Erreurs et Résultats Sans Bavure

Imagine you cut a metal sheet and see rough burrs on the edge. Sometimes, you might even find chips on your cutting blade. You can stop these problems by ensuring proper shear blade clearance adjustment. If you set the clearance just right, you achieve smooth cuts and fewer burrs. Your blades will also last longer and […]

Lames de Cisaille à Travail à Chaud H13 : Maîtriser la Coupe de Métaux à Haute Température et le Cisaillement de Billets

You need cutting tools that can handle very high heat. These tools must stay sharp for a long time. Hot work shear blades made from H13 steel are tough and dependable. They work well for hard jobs. H13 steel is special because it does not get tired from heat. It does not wear out fast. It can […]

Réaliser des Coupes Sans Bavure avec des Lames de Cisaille à Guillotine de Précision

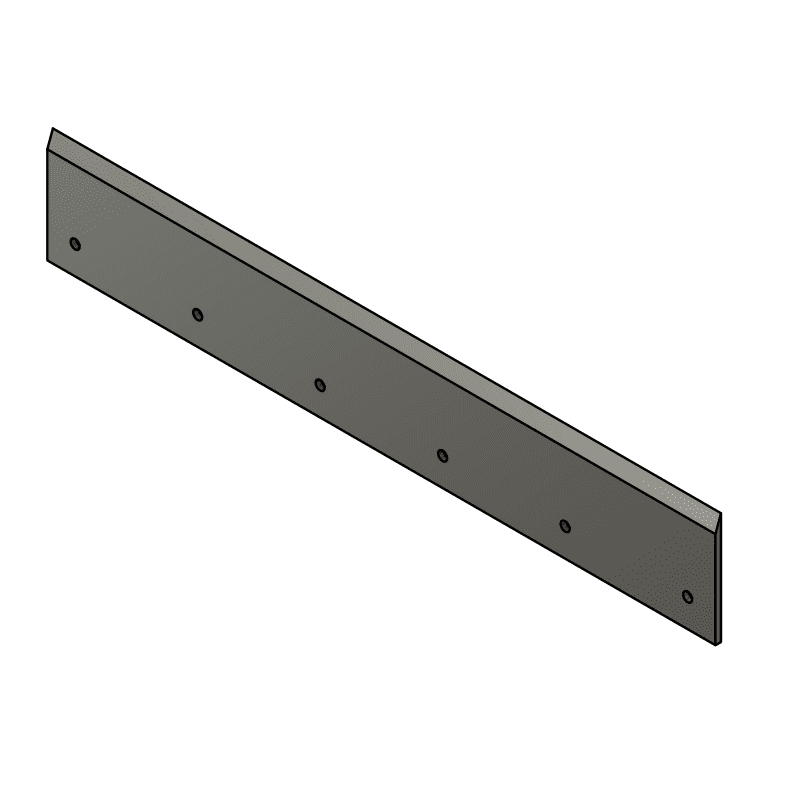

You can get zero-burr cuts by using good blades. You also need to set up the machine right. Skilled workers help a lot too. Precision Guillotine Shear Blades from Metal Industrial give you great results. These blades help you work faster and better. Blades with special edges and strong materials work best. Taking care of your blades […]

Lames de Cisaille D2 : Pourquoi l'Acier D2 Est le Roi de la Coupe de Métaux à Froid

D2 steel shear blades are great for cutting cold metal. These blades stay sharp for a long time. They do not wear out quickly. You get the same good results every time. Many workers pick D2 steel because it is very hard. It keeps its shape well and does not rust easily. Metal Industrial works hard […]

Lames de Guillotine vs. Lames de Cisaille : Quelle est la Différence et Laquelle Est la Meilleure pour Votre Travail ?

Imagine you have to cut thick metal sheets for a big job. You need to pick between guillotine vs shear blades. Guillotine shears move straight down and are best for long, straight cuts. Shear blades, like the ones from Metal Industrial, are strong and accurate, working on many materials and shapes. Picking the right tool changes […]

Guide des Matériaux de Lames de Cisaille : D2 vs. A2 vs. 5160 vs. Carbure — Quel Est le Meilleur Choix ?

Choosing the right shear blade material depends on what you cut. It also depends on how often you use your blades. You need blades that can handle hard jobs. You want blades that last a long time. Special heat treatments like quenching and tempering make blades harder. These treatments also make blades stronger. The table below shows common problems […]

L'Acier Inoxydable Rouille-t-il ? — Comparaison de la Corrosion des Grades Courants de Lames Industrielles

Stainless steel can rust, contrary to popular belief that it never does. It’s important to understand how each grade works before selecting a blade, as not all stainless steel types prevent stainless steel rust in the same manner. The environment where you work and the composition of your blade both play significant roles. Recent research indicates that […]

Noircissement des Lames en Acier Inoxydable : Pourquoi Cela Arrive et Comment le Prévenir

You may see your stainless steel blade turn black. You might think it should stay shiny. Stainless steel blade blackening means dark spots show up. These spots or patches can appear on the surface. This usually happens because of oxidation. Oxidation is also called rouging. Many things can cause this change. Some common causes are: Touching non-stainless […]