Você usa Lâminas de corte rotativas para fita adesiva to cut sticky materials. These blades help you handle tough sticky problems. Sticky problems can slow down how fast you work. If you pick good blades, you get cleaner cuts. Cleaner cuts mean you waste less tape. Blades made from tungsten carbide and high-speed steel last longer. These materials also help blades work better. You can change blade features to fit your needs. Some companies buy better blades for their work. These companies work up to 20% faster. They also have fewer stops in production.

Principais conclusões

- Rotary slitter blades cut big rolls of tape into small strips. These blades are important for working with sticky tape.

- You need to pick the right blade type for your tape. Circular blades or razor blades work for different tape thickness and stickiness.

- Sharp and clean blades help make smooth cuts. This means less tape gets wasted. It also helps work get done faster.

- Cleaning blades often stops glue from building up. Glue can make blades dull and mess up the cuts.

- Blades are made from different materials like tungsten carbide or high-speed steel. These materials last longer and work better for sticky tape.

- Some blades are custom-made for special cutting jobs. Custom blades help get better results for special tape types.

- Workers should learn how to spot worn blades. Dull edges or rough cuts mean the blade needs fixing. This keeps tape cuts good.

- Talking with suppliers can help you pick the best blades. Suppliers also help you take care of your blades.

Rotary Slitter Blades for Tape and Adhesives

What Are Rotary Slitter Blades

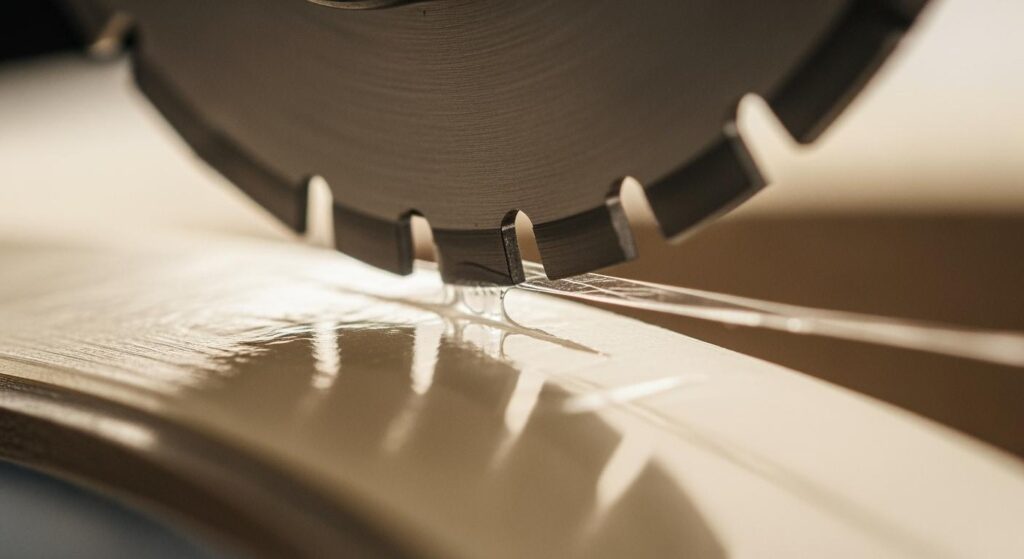

Rotary slitter blades cut big rolls of tape into smaller strips. These blades spin fast and slice materials neatly. Machines use rotary slitter blades for sticky tapes, films, and flexible things. Blades come in many shapes and sizes. Some blades have sharp edges for smooth cuts. Some blades have coatings to stop glue from sticking. You pick a blade that fits your material and job.

Blades work best when they are sharp and clean. Dull blades can rip tape and make rough edges. Sharp blades give straight, smooth cuts. Many industries use these blades. They help make products faster and waste less.

Applications in Tape Slitting

Rotary slitter blades are important in many jobs. You use them to cut pressure-sensitive tapes and double-sided tapes. They also cut protective films, paper tapes, and liners without glue. Machines use these blades to make labels, packages, and textiles.

Here is a table that shows where rotary slitter blades are used and what they do:

| Indústria | Descrição da aplicação |

|---|---|

| Adhesive Tape Manufacturing | Cutting pressure-sensitive tapes like electrical, medical, and industrial tapes. |

| Label Manufacturing | Cutting label materials such as paper, film, and foil for custom labels and tags. |

| Embalagem | Cutting different packaging materials. |

| Produção de papel | Cutting paper products for many uses. |

| Têxteis | Cutting textile materials for making products. |

You see rotary slitter blades in packaging, paper, textiles, and tape making. Each job needs a blade that matches the tape and material. You pick blades based on how thick, sticky, and fast your process is.

Cutting Sticky Materials

Cutting sticky stuff is hard. Glue can build up on blades. This makes blades dull faster and causes more friction. Dull blades make rough, uneven cuts. These problems can hurt your product quality.

You need to keep tape steady while cutting. If tape moves, strips can be crooked or wrinkled. Clean and sharp blades help stop tearing. Managing glue buildup stops drag and damage. You also need to control tape tension. Good tension keeps tape flat and helps you cut straight.

Here are some tips for cutting sticky materials:

- Use clean, sharp blades to stop tearing.

- Keep material steady for good cuts.

- Control glue buildup to avoid drag and damage.

Tip: Clean your blades often and take care of them. This helps your rotary slitter blades last longer and work better.

Rotary slitter blades for tape help you solve sticky problems. You get smoother cuts, less waste, and better results.

Blade Types for Tape and Adhesives

Lâminas Circulares

Suitable Tape Types

Circular blades can cut many kinds of tape. They work well with pressure-sensitive tapes and double-sided adhesive tapes. You can use them for thick adhesive tapes too. These blades also cut protective films and paper tapes. Non-adhesive liners are easy for circular blades. Most slitter machines use circular blades, so they are popular.

- Pressure-sensitive tapes

- Double-sided adhesive tapes

- High-tack and thick adhesive tapes

- Protective films

- Paper tapes

- Non-adhesive liners

Some circular blade models are common for tape and adhesives:

- 2-013-K: Good for cutting adhesive tape.

- 2-020-K: Cuts tape well and is reliable.

- 2-020-Z: Has a special coating to lower friction.

Vantagens

Circular blades make cuts that are neat and exact. If you keep them sharp, they last a long time. These blades work fast, so you finish jobs quickly. Shear slitting with circular blades gives smoother cuts than other ways. You see fewer rough edges and less tape waste. Circular blades do not get sticky as fast, so you stop less to clean.

Tip: Circular blades stay sharp and strong, so you do not need to change them often.

Desvantagens

You need to clean circular blades more when tape is very sticky. These blades can cost more at first than other types. Some tapes are extra sticky and may need special coatings or more blade changes.

Application Example: High-Tack Tape

Circular blades are used a lot for cutting high-tack adhesive tapes in factories. Their strong design helps them stay sharp and cut well. Even sticky tapes are easy for these blades. In car tape making, circular blades help keep edges smooth and stop glue from building up. This means less cleaning and your machine works better.

Lâminas de barbear

Suitable Tape Types

Razor blades are best for thin films and tapes. They work well with low to medium tack adhesive tapes. You can use them for protective films and paper tapes. Razor blades are good for cutting delicate materials.

- Thin films and tapes

- Low to medium tack adhesive tapes

- Protective films

- Paper tapes

Vantagens

Here is a table that shows why razor blades are good for tape slitting:

| Vantagem | Descrição |

|---|---|

| High precision | Razor blades make very exact cuts and waste less tape. |

| Corte de alta velocidade | You can cut lots of tape quickly with razor blades. |

| Minimal burrs | Sharp blades leave fewer rough spots, so you do not need much fixing. |

| Versatilidade | Razor blades can cut paper, plastic, rubber, and textiles. |

| Low tooling costs | The tools are simple and cheap, so you save money. |

| Consistent quality | Razor blades give you good cuts every time. |

Razor blades make clean cuts and keep quality high. These blades are easy to change, so you do not stop production for long.

Desvantagens

Razor blades do not last long, especially with sticky or rough adhesives. They are not good for thick or very sticky tapes. You may need to change razor blades often to keep cuts smooth.

Score Blades

Suitable Tape Types

Score blades, also called crush slitting blades, are best for thick or soft materials. You use them for reinforced tapes and special adhesive products. Some pressure-sensitive tapes can be cut with score blades. These blades work well for tough or layered tapes.

- Thick adhesive tapes

- Reinforced tapes

- Specialty adhesive products

- Some pressure-sensitive tapes

Vantagens

Score blades are cheap and simple to set up. They can cut materials that other blades cannot. These blades are easy to take care of and work well for making lines or holes without cutting all the way through.

Note: Score blades are good for cutting pressure-sensitive tapes because they handle thick and sticky materials easily.

Desvantagens

Score blades do not make cuts as smooth as other blades. They can make dust and heat when cutting. You might see marks or fuzzy edges on the tape. These blades only work for some jobs and may not cut sticky tapes very cleanly.

Lâminas especiais

Suitable Tape Types

Specialty blades are used for cutting special tapes. These tapes have unique adhesives or layers. Standard blades cannot cut these tapes well. Specialty blades work for:

- Specialty adhesive products

- Custom or engineered tapes

- Reinforced tapes

- Filmes laminados

Specialty blades can cut tapes with coatings or odd thickness. They also work for tapes with complex shapes. If you need perfect edges or strong adhesives, specialty blades help you get better cuts.

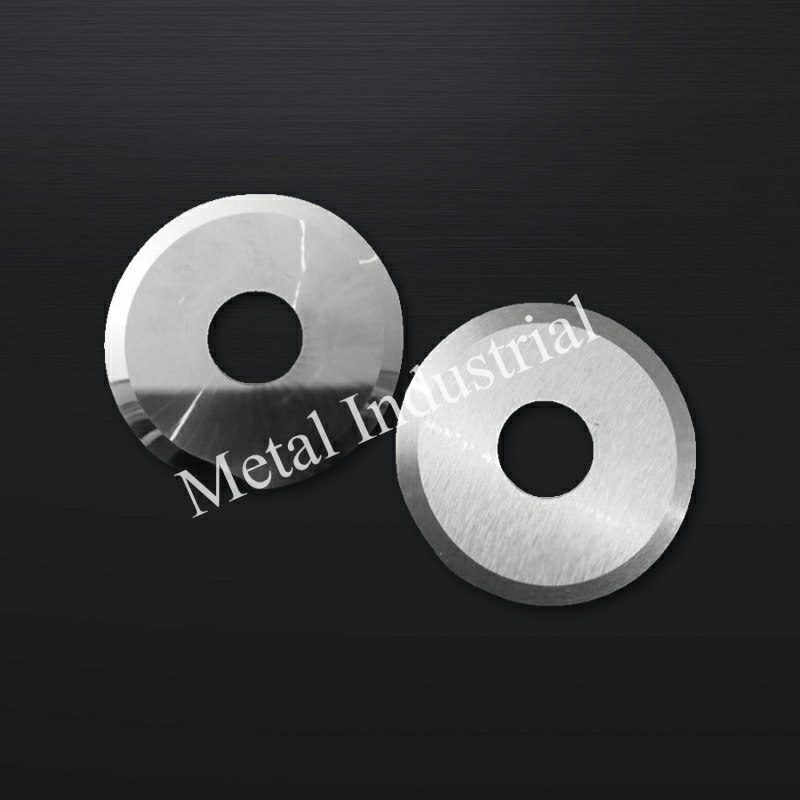

Vantagens

Specialty blades have many good points for rotary slitter blades for tape. They are made from high-speed steel, tool steel, or tungsten carbide. These materials make blades last longer and stay strong. Specialty blades come in shapes like solid rings, segmented rings, or custom profiles. You can pick the shape that fits your job.

Some specialty blades have grooves or steps. These features help guide tape and make cuts more accurate. You can change specialty blades to fit your machine and tape. This helps you get cleaner cuts and less waste.

Here is a table that shows what makes specialty blades special:

| Feature Type | Descrição |

|---|---|

| Materiais Comuns | High-Speed Steel, Tool Steels, Tungsten Carbide for durability and performance |

| Common Shapes | Solid rings, segmented rings, custom profiles for precision and efficiency |

| Design Considerations | Grooved surfaces, stepped designs for better guiding and cutting accuracy |

Tip: Specialty blades help you fix hard cutting problems. You can use them for tapes that need special care or have tricky adhesives.

Desvantagens

Specialty blades cost more than regular blades. You might wait longer for lâmina personalizada designs. These blades are best for certain jobs, not all tapes. Specialty blades need careful setup and sometimes expert advice to pick the right one.

Comparing Blade Types

You should look at blade types before picking rotary slitter blades for tape. Each blade type has good and bad sides. Circular blades make clean cuts and work for sticky tapes. Razor blades are very exact for thin films. Score blades cut thick or strong tapes. Specialty blades are for custom or special tapes.

Here is a table that compares blade types for cutting and how long they last:

| Tipo de lâmina | Precisão de corte | Durabilidade | Suitable Tape Types |

|---|---|---|---|

| Circular | Alto | Alto | Pressure-sensitive, high-tack, double-sided, protective films, paper tapes |

| Razor | Muito alto | Baixo | Thin films, low-medium tack, protective films, paper tapes |

| Score | Médio | Médio | Thick, reinforced, specialty adhesive products |

| Specialty | Muito alto | Muito alto | Custom, engineered, reinforced, specialty adhesive products |

Note: Match the blade type to your tape and adhesive. This helps you get the best cuts and keeps your work going smoothly.

When you choose rotary slitter blades for tape, think about your tape, adhesive, and how fast you need to work. Specialty blades are good for hard jobs. Circular, razor, and score blades work for most normal jobs. You can ask your supplier for custom blades if you need something special.

Blade Materials and Performance

Aço ferramenta

Tool steel is used a lot in rotary slitter blades for tape. It gives blades a strong edge that stays sharp for many cuts. You can use tool steel blades for different tapes, like pressure-sensitive and double-sided adhesive tapes. Tool steel does not bend or chip easily, so cuts are always reliable. These blades are good for jobs that need strength and accuracy. You can sharpen tool steel blades without much trouble. This helps your slitting machine work well. Tool steel can handle some sticky glue, but you should clean blades often to keep them working right.

Tip: Tool steel blades are a smart pick if you want good performance and do not want to spend too much.

Carboneto de tungstênio

Tungsten carbide is great for rotary slitter blades for tape. These blades last much longer than most other blade materials. Tungsten carbide blades stay sharp even when cutting sticky or tough tapes. You can use these blades for high-tack adhesives and thick tapes. Tungsten carbide blades can last up to ten times longer than high-speed steel blades in hard jobs. These blades stay sharp for a long time and cut tough materials faster than high-speed steel blades. You do not need to change tungsten carbide blades often, so you save time. These blades do not wear out quickly and keep their edge even with lots of use. If you cut sticky tapes that make blades dull fast, tungsten carbide helps you get clean cuts and work faster.

Note: Tungsten carbide blades cost more, but you save time and money because you do not change blades as much.

Aço de alta velocidade

High-speed steel gives you both speed and sharpness for rotary slitter blades for tape. You can use high-speed steel blades for many tapes, like thin films and medium-tack adhesives. These blades cut fast and stay sharp for many jobs. High-speed steel blades work well in machines that cut tape quickly. You get clean cuts and steady results. These blades do not last as long as tungsten carbide, but you can sharpen them easily. High-speed steel is a popular choice when you want both speed and good quality.

Aqui está um table that shows how blade material affects cutting sticky adhesive tapes:

| Material da lâmina | Durabilidade | Precisão de corte | Resistance to Wear |

|---|---|---|---|

| Aço de alto carbono | Moderado | Bom | Moderado |

| Carboneto de tungstênio | Alto | Excelente | Excepcional |

| Cerâmica | Moderado | Alto | Alto |

Tip: Pick high-speed steel blades if you want fast, sharp cuts and easy care for your tape slitting jobs.

Lâminas Revestidas

It is hard to cut tape because glue sticks to blades. Sticky glue can slow you down and make cuts messy. Coated blades help fix these problems. Makers put special coatings on the blade surface. These coatings use things like titanium nitride or ceramic. The coating makes a smooth layer that stops glue from sticking.

You get many good things when you use coated blades for sticky tapes:

- Coated blades last longer. The coating keeps the blade safe from damage, so you do not need new blades often.

- The coating stops chemical damage. Sticky adhesives can hurt normal blades, but coated blades do not get damaged as easily.

- You get better cuts. The smooth coating helps the blade move through tape without dragging or ripping.

- Coated blades help keep your work clean. Less glue sticks to the blade, so you do not have to clean as much.

You can also use coated razor blades and solid ceramic blades to stop glue from building up. Some blades get polished to make them even smoother. This means less glue and dust will stick. Sharp tungsten carbide edges also help stop glue from building up and keep tape edges neat.

Tip: If you cut tape with strong glue, try coated blades. You will see less glue on your blades and get cleaner cuts.

Material Selection for Sticky Tapes

Picking the right blade material is important for sticky tapes. Rotary slitter blades for tape come in different materials. Each material works best for certain jobs.

Look for these things when you choose a blade for sticky tapes:

- High resistance to glue buildup

- Strong edge that stays sharp

- Can handle tough or thick glue

Here is a table to help you compare blade materials for sticky tape cutting:

| Material da lâmina | Melhor para | Benefício principal | Notas |

|---|---|---|---|

| Carboneto de tungstênio | High-tack, thick adhesives | Lasts long, sharp edge | Stops glue buildup, less downtime |

| Coated Razor Blades | Strong glue, thin films | Less glue sticks | Smooth surface, easy to clean |

| Solid Ceramic | Sticky tapes, clean cuts | Stops glue and dust | Needs careful use |

| Aço ferramenta | Regular sticky tapes | Good price and strong | Needs cleaning often |

| Aço de alta velocidade | Fast cutting, medium glue | Sharp, easy to sharpen | Not for very sticky tapes |

You can ask your supplier about blades with extra polishing. This makes the blade even smoother. Less glue and dust will stick, so you get better cuts.

Note: Always match your blade material to your tape type. The right blade helps you cut faster, waste less, and keep your rotary slitter blades for tape working longer.

If you cut many kinds of tape, keep a few blade choices ready. You can switch blades based on the tape and glue you need to cut. This helps you get the best results from your rotary slitter blades for tape every time.

Blade Selection for Tape Applications

Picking the right rotary slitter blades for tape helps you make clean cuts. This also helps your work go faster. You need to think about a few things before you choose a blade.

Key Parameters

Tape Type

You should know what tape you want to cut. Some tapes are thin and soft. Others are thick and strong. Pressure-sensitive tapes, double-sided tapes, and protective films need different blades. Razor blades work best for thin films. Circular or score blades are good for thick or reinforced tapes. If you use special tapes, you might need custom slitter machine blades.

- Razor blades are for thin films and tapes.

- Circular or score blades are for thick adhesive tapes.

- Custom slitter machine blades are for specialty tapes.

Adhesive Properties

The glue on your tape changes which blade you need. Sticky glue can build up on blades and slow your machine. Blades with coatings like Titanium Nitride or Teflon help stop glue from sticking. Thin knives with small tips give cleaner cuts and less drag. Double bevel knives with angles between 20° and 25° work well for sticky tapes. Strong blade materials like D2, M2, or carbide last longer when cutting tapes with tough glue.

Tip: Keep your blades sharp and clean. This stops glue problems and keeps cuts smooth.

Slitting Speed

Think about how fast your machine works. Fast slitting needs blades that stay sharp and strong. High-speed steel blades are good for quick jobs in packaging and textiles. Carbide blades last longer and work well for hard jobs, but cost more. If your machine is slow, you can use blades that are not as hard.

- Use high-speed steel or carbide blades for fast slitting.

- Use tool steel or coated blades for slow slitting.

Matching Blade to Tape

You need to match your rotary slitter blades for tape to your tape and glue. Start by checking tape thickness and glue strength. Razor blades are best for thin tapes with light glue. Circular or carbide blades are better for thick tapes with strong glue. Custom slitter machine blades are needed for special tapes.

Check your machine settings too. Blade type, blade material, and speed all change your results. Using the wrong blade can make rough edges, waste tape, or cause more stops.

Here is a simple checklist to help you pick your blade:

- Check tape thickness and glue type.

- Pick blade material for your tape and glue.

- Choose blade shape and edge for your machine.

- Make sure your blade matches your slitting speed.

Note: If glue is sticky or cuts are rough, try blades with smooth coatings or sharper edges.

Opções de personalização

You can get custom blades if you have special cutting needs. Custom slitter machine blades let you pick the right material, hardness, and edge shape. You can also choose blades with special coatings or shapes to work better and waste less.

| Aspecto de personalização | Descrição |

|---|---|

| Special Cutting Needs | Blades can be made for special cutting jobs. |

| Seleção de Materiais | Companies can pick the best material for their job. |

| Hardness and Edge Shape | You can choose how hard and what shape the blade edge is. |

| Performance Enhancement | Custom blades help you work better and waste less tape. |

If you want to know more about custom blades, visit the página de lâminas personalizadas.

Working with a good supplier helps you get the best rotary slitter blades for tape. Nanjing Metal Industrial gives custom solutions, high-quality blades, and expert help.

| Beneficiar | Descrição |

|---|---|

| Soluções Personalizadas | Suppliers can make blades for your job, so you work better. |

| Lâminas de alta qualidade | Good blades meet standards and help keep your products good. |

| Serviços Profissionais | Experts can help you work better and make your tape cutting smoother. |

Tip: Work with your supplier to get custom slitter machine blades that fit your tape and machine. This helps you cut better and waste less.

You can cut tape better by picking the right rotary slitter blades for tape, matching them to your tape and glue, and using custom blades if you need them. Good blade choices help you work faster, waste less, and keep your machines working well.

Manutenção e Longevidade

Cleaning Adhesive Residue

Sticky adhesives can pile up on rotary slitter blades for tape. This sticky stuff makes blades dull and causes rough cuts. You should clean your blades after every time you use them. Use a soft cloth that does not leave lint and a cleaner made for blades. This way, glue comes off without scratching the blade. Do not use rough cleaners or metal tools. These can hurt the blade edge and make it wear out faster.

- Wipe blades with a soft, lint-free cloth.

- Use a blade-safe cleaner to get rid of sticky glue.

- Clean blades after each time you finish cutting.

- Never use metal scrapers or strong chemicals.

Tip: Cleaning your rotary slitter blades for tape often keeps them sharp and ready for work.

Afiação e Substituição

You need to keep rotary slitter blades for tape sharp for good cuts. Dull blades can rip tape and slow you down. Check your blades every week to see if they are still sharp. Look for burrs, scratches, or extra glue stuck to the blade. If you see these signs, sharpen or replace the blade.

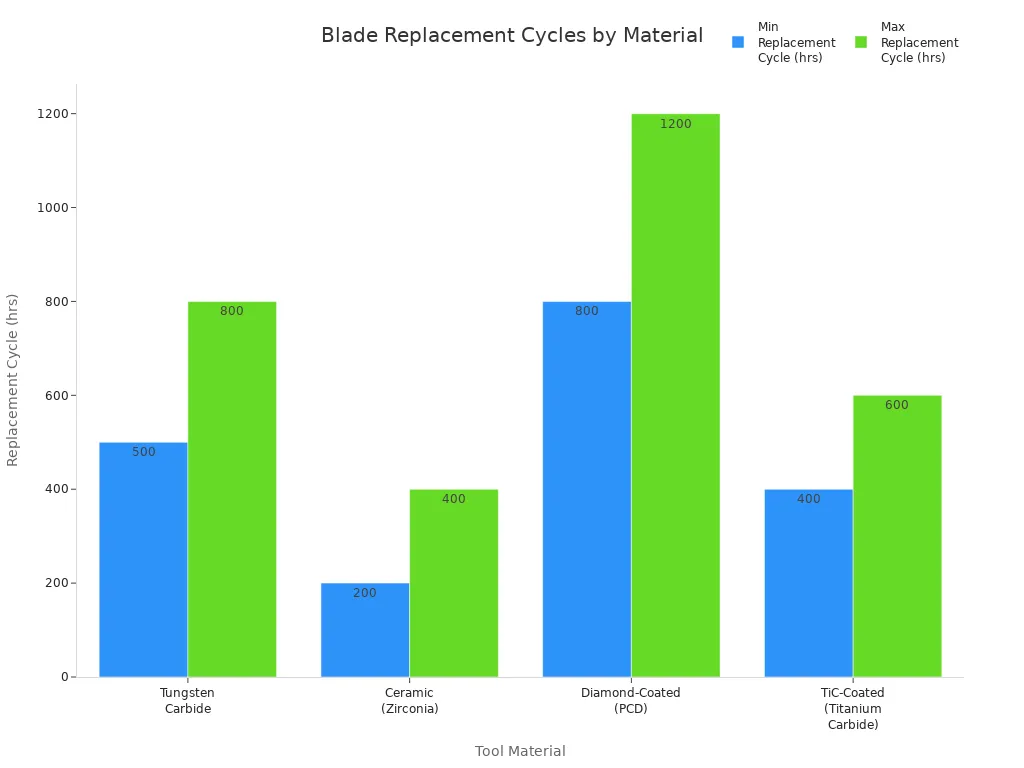

How often you change blades depends on what they are made of and what tape you cut. Here is a table that shows when to replace different blades:

| Tool Material | Applicable Tapes | Reference Replacement Cycle | Fatores-chave | Replacement Warnings |

|---|---|---|---|---|

| Carboneto de tungstênio | General transparent/BOPP/sealing | 500–800 hrs (80,000–100,000 cuts) | Tape tack (high-tack shortens cycle by 20%) | Continuous burrs, increased adhesive residue |

| Ceramic (Zirconia) | Medical-grade/optically clear | 200–400 hrs (50,000–60,000 cuts) | Blade temp (≤120℃), impact load | Edge chipping >0.03mm, reduced light transmittance |

| Diamond-Coated (PCD) | High-tack foam/electronic | 800–1200 hrs (120,000–150,000 cuts) | Coating anti-adhesion, cleaning frequency | Local coating peeling, tape sticking |

| TiC-Coated (Titanium Carbide) | Aluminum foil/high-temp tape | 400–600 hrs (60,000–80,000 cuts) | Coating stability in high temps | Coating discoloration, carbonized cut edges |

Note: Sticky tapes can make blades wear out up to 20% faster. If you see burrs or lots of glue, it is time to sharpen or change the blade.

Melhores práticas de armazenamento

Storing rotary slitter blades for tape the right way helps them last longer. Always keep blades in a dry place with good air flow. Wet air can cause rust, especially on carbon steel blades. Make sure blades are dry before you put them away. Put a thin layer of oil on the blade to stop rust. Use cases or soft cloth bags to keep dust and water away.

- Store blades in a dry, cool place.

- Oil blades a little before storing for a long time.

- Use cases or cloth bags for protection.

- Never put away wet blades.

- Clean and oil blades often.

Tip: Taking care of your rotary slitter blades for tape and storing them right keeps them ready for your next job.

Sinais de desgaste

You need to check rotary slitter blades for tape often. Worn blades can cause problems in your cutting process. If you spot signs of wear early, you can fix issues before they get worse. This helps you keep your production smooth and your tape quality high.

When you use rotary slitter blades for tape, you may notice changes in how the blade cuts. Sometimes, the blade does not slice as easily. You might see rough edges or uneven strips. These are clues that your blade needs attention.

Here are some common signs that show your rotary slitter blades for tape are wearing out:

- You see small chips or cracks on the blade edge. These chips can happen after cutting tough or sticky tapes.

- The blade edge looks rounded or blunt. A sharp blade should have a clean, straight edge. If it looks dull, it will drag through tape instead of slicing.

- You feel more resistance when cutting. If you need to push harder, the blade is probably dull. This extra force can stress your machine and slow down your work.

- The cut quality drops. You may notice rough or jagged edges on the tape. Clean cuts mean the blade is sharp. Bad cuts mean it is time to sharpen or replace the blade.

- Burrs form on the tape after cutting. Burrs are small bits of tape or adhesive left on the edge. More burrs mean the blade is not sharp enough.

- The width of the tape strips changes. If you see strips that are not the same size, the blade may be damaged or dull. This can lead to wasted material.

You can use the table below to help you spot signs of wear in rotary slitter blades for tape:

| Sign of Wear | Descrição |

|---|---|

| Visible Chips or Nicks | Small chips, dents, or cracks on the edge after cutting tough materials. |

| Rounded or Blunt Edges | Blade edge looks dull, causing dragging instead of slicing. |

| Increased Cutting Resistance | You need more force to cut, which stresses the machine. |

| Declining Cut Quality | Cuts become rough or jagged, showing the blade needs sharpening. |

| Increased Burr Formation | More burrs left on tape after cutting, meaning the blade is not sharp. |

| Inconsistent Cut Widths | Tape strips vary in width, showing the blade is dull or damaged. |

Tip: Check your rotary slitter blades for tape before each shift. Early detection of wear helps you avoid bigger problems and keeps your cuts clean.

If you notice any of these signs, you should clean, sharpen, or replace your blade. Keeping your rotary slitter blades for tape in good shape helps you save time and reduce waste. Regular checks make your slitting process safer and more efficient.

You can train your team to spot these signs. When everyone knows what to look for, you catch problems faster. This keeps your machines running well and your tape products looking their best.

Practical Tips for Tape Manufacturers

Implementing Best Practices

You can get better slitting results by using some simple steps. Make a schedule to check your rotary slitter blades for tape often. Look at the blade before each work shift. Clean the blade after every use to get rid of dust and glue. This helps keep the blade sharp for the next job.

Put a little oil on the blade to stop rust. Always make sure the blade is lined up right in the machine. If the blade is not lined up, you might get uneven cuts and waste tape. Check knife holders often. Look for worn parts, add oil, and change old pieces. Taking care of knife holders helps you get good cuts and makes blades last longer.

Here are some steps you can follow:

- Use sharp blades for smooth cuts. This stops dust and rough tape edges.

- Try coated blades if you want them to last longer and cut better.

- Use solid ceramic or tungsten carbide blades for blades that last even longer.

Tip: Keeping up with blade and knife holder care can really help you make adhesive tape better.

Treinamento do Operador

Operators are important for keeping rotary slitter blades for tape working well. Teach your team to look for dull blades or rough cuts. Show them how to clean and handle blades safely. Make sure they know how to check blade alignment and tension before starting the machine.

Use easy checklists to help operators remember what to do. For example:

- Look for chips or dull spots on blades.

- Clean blades after every shift.

- Check if the blade is lined up and tight.

- Tell someone if there is a problem.

A trained operator can find problems early. This helps stop delays and keeps your machines running well.

Suporte ao Fornecedor

You do not have to fix every problem by yourself. Good suppliers can help you get the best from your rotary slitter blades for tape.

A helpful supplier can do these things for you:

| Support Area | How It Helps You |

|---|---|

| Blade Selection | Helps you pick the right blade for your tape and glue |

| Maintenance Advice | Shows you how to care for blades and knife holders |

| Soluções Personalizadas | Makes blades for special or hard jobs |

| Solução de problemas | Helps you fix cutting problems fast |

Note: Working closely with your supplier gives you new blade ideas and the best ways to use them.

If you follow these tips, your rotary slitter blades for tape will work better and help you make more good adhesive tape.

Troubleshooting Slitting Issues

You may face problems when using rotary slitter blades for tape. These issues can slow down your work or lower your product quality. Knowing how to spot and fix these problems helps you keep your slitting process smooth.

Common Slitting Problems

Here are some issues you might see:

- Rough or jagged tape edges

- Tape tearing or stretching

- Adhesive buildup on blades

- Uneven tape widths

- Blade chipping or dulling too fast

- Tape sticking to the blade

Causes and Solutions

You can use this table to match problems with their likely causes and solutions:

| Problema | Possible Cause | Solução |

|---|---|---|

| Rough or jagged edges | Dull blade, wrong angle | Sharpen blade, check blade alignment |

| Tape tearing | Blade too dull, wrong tension | Use sharper blade, adjust tape tension |

| Adhesive buildup | Sticky tape, no coating | Clean blade, use coated or polished blade |

| Uneven tape widths | Desalinhamento da lâmina | Realign blade, check machine settings |

| Blade dulls quickly | Cutting high-tack tape | Use harder blade material, clean often |

| Tape sticks to blade | No anti-stick coating | Try coated blade, reduce blade heat |

Tip: Always check your rotary slitter blades for tape before starting a new job. Early checks help you catch problems before they get worse.

Step-by-Step Troubleshooting

- Inspecione a lâmina

Look for chips, dull spots, or glue on the blade edge. Replace or clean the blade if needed. - Verifique o alinhamento da lâmina

Make sure the blade sits straight in the holder. Misaligned blades cause uneven cuts. - Adjust Tape Tension

Too much or too little tension can stretch or wrinkle tape. Set the tension to keep tape flat. - Limpe a lâmina

Wipe off glue and dust after each shift. Use a soft cloth and blade-safe cleaner. - Review Machine Settings

Check speed, pressure, and blade angle. Small changes can fix many cutting problems.

When to Ask for Help

If you try these steps and still have trouble, talk to your blade supplier or machine technician. They can help you find the right rotary slitter blades for tape or adjust your setup for better results.

Note: Keeping a log of problems and solutions helps you spot patterns. This makes future troubleshooting faster and easier.

You can solve most slitting issues by checking your blades, cleaning often, and making small adjustments. Good troubleshooting keeps your rotary slitter blades for tape working well and your production on track.

You should pick the right rotary slitter blades for tape. This helps you make clean cuts and waste less tape. The blade’s material and type matter a lot. Taking care of blades helps you work faster. It also keeps your machines working well. Custom blades can fix hard cutting problems. Experts can help you choose the best blade. If you want better results, ask a sales engineer for help with rotary slitter blades for tape. Contact us here to get started.

Perguntas frequentes

What are rotary slitter blades for tape?

Rotary slitter blades for tape cut wide rolls of tape into smaller strips. You use these blades in machines to get clean, straight cuts. They help you handle sticky adhesives and different tape types.

How do you choose the right blade for sticky tape?

You look at tape thickness and adhesive strength. Pick rotary slitter blades for tape made from tungsten carbide or coated steel for sticky tapes. Ask your supplier for advice if you need help.

How often should you clean rotary slitter blades for tape?

You should clean blades after every use. Sticky adhesives build up fast. Regular cleaning keeps blades sharp and helps you get better cuts.

What signs show rotary slitter blades for tape need replacing?

Watch for dull edges, chips, or rough tape cuts. If you see more adhesive on the blade or uneven tape strips, you should replace or sharpen the blade.

Can you use rotary slitter blades for tape on different materials?

Yes, you can use rotary slitter blades for tape on paper, film, rubber, and textiles. You need to match the blade type and material to your job for best results.

Why do rotary slitter blades for tape get dull quickly with sticky adhesives?

Sticky adhesives stick to the blade edge. This causes friction and makes the blade dull faster. Cleaning and using coated blades help slow down wear.

How do you store rotary slitter blades for tape safely?

Store blades in a dry, cool place. Use blade cases or cloth bags. Add a thin layer of oil to prevent rust. Always keep blades away from moisture.

Veja também

Principais Erros na Solução de Problemas de Lâminas de Corte Rotativas e Como Corrigi-los

Prolongue a vida útil da sua lâmina: O guia completo para afiar lâminas de cortadoras rotativas.

Lâminas de Corte Rotativas de Alta Precisão para o Corte de Filmes e Folhas

As Melhores Lâminas de Corte Rotativas para o Corte de Metal

Como Alcançar Cortes Perfeitos com Lâminas de Corte Rotativas para Papel