Escurecimento de Lâminas de Aço Inoxidável: Por Que Acontece e Como Prevenir

You may see your stainless steel blade turn black. You might think it should stay shiny. Stainless steel blade blackening means dark spots show up. These spots or patches can appear on the surface. This usually happens because of oxidation. Oxidation is also called rouging. Many things can cause this change. Some common causes are: Touching non-stainless […]

Faca de Tungstênio: Vale a Pena? Prós, Contras e Aplicações na Indústria

If you want a knife that lasts longer and needs less stopping, a tungsten knife could be a good buy. Tungsten carbide is special in industry because it does not wear out fast. It keeps its edge sharp much longer than steel. Tungsten carbide products use about 65% of all tungsten in the world. This makes them […]

Como Afiar e Manter Facas de Carboneto de Tungstênio

Sharpening and taking care of tungsten carbide knives can be challenging. The material does not wear down easily, but it can chip if you are not careful. Some people make the blade too hot, which can cause tiny cracks. Using softer abrasives than tungsten carbide can damage the blade. To maintain tungsten carbide knives effectively, keeping a […]

Por Que as Facas de Carboneto de Tungstênio Lascam — Modos de Falha Comuns e Como Evitá-los

Tungsten Carbide Knives can chip if you use them the wrong way or if they get hit hard. These knives are very hard, so they stay sharp for a long time. But you must be careful when you use them. Metal Industrial Tungsten Carbide Knives are very strong in factories. Many people say these knives last […]

Tungsten Carbide vs Steel for Industrial Blades: Performance, Wear & Cost

When you compare tungsten carbide vs steel blades, you notice significant differences. Tungsten carbide blades are much harder and do not wear out quickly. They maintain their sharpness even under high temperatures. On the other hand, steel blades are better at absorbing hits and shocks. Initially, steel is less expensive. The table below highlights these main differences: […]

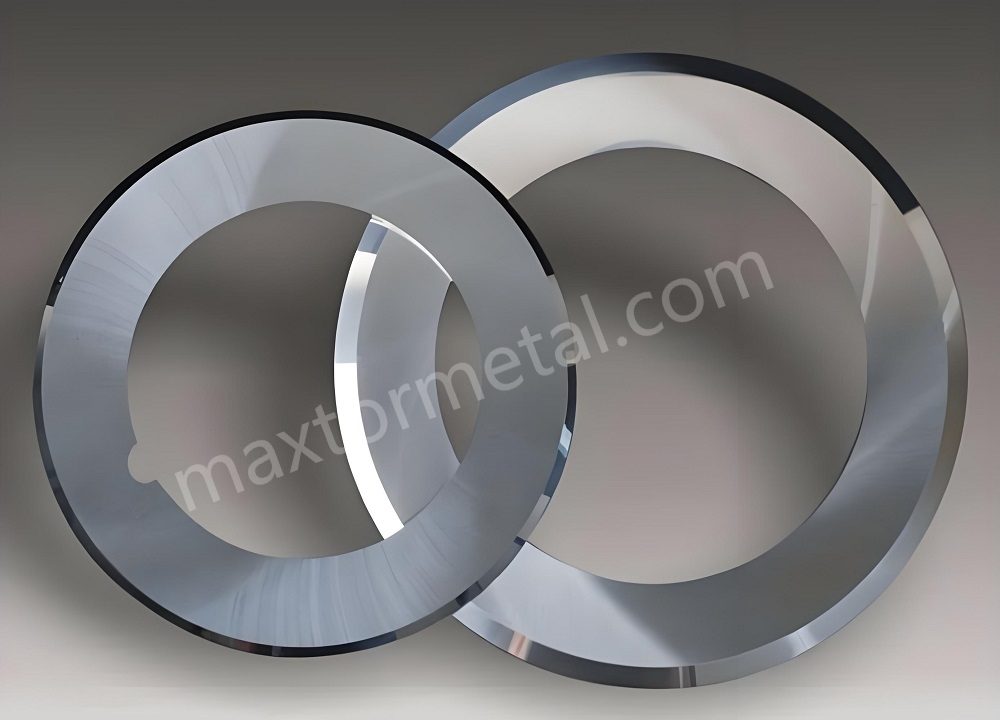

Lâminas de Corte Rotativas Aftermarket vs. OEM: Uma Análise Custo-Benefício

You want blades that give you good value. Many people pick OEM rotary slitter blades. These blades have high quality. They last a long time. They work well and do not break easily. When you choose blades, you think about cost. You should also consider how long they will last. Check how often they need fixing. […]

Precision and Durability: Rotary Slitter Blades for Rubber & Plastic Cutting

You use rotary slitter blades for rubber and plastic to make accurate and strong cuts. Good blades help you get cleaner cuts and last longer. This is true when you pick blades that fit your needs. Companies like Nanjing Metal Industrial have many choices. They focus on making blades that work well for you. The table below shows how […]

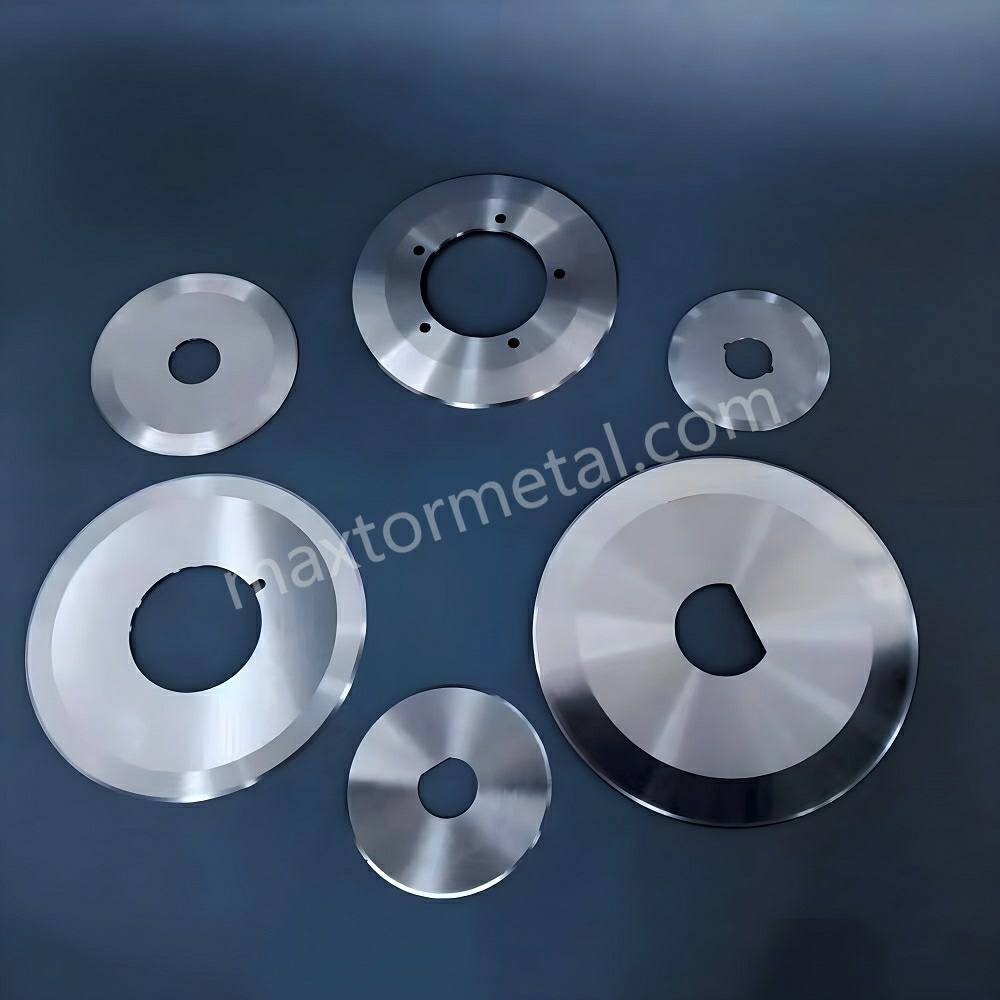

5 Maneiras Comprovadas de Estender a Vida Útil das Lâminas de Corte Rotativas

You want your rotary slitter blades to last a long time and extend rotary slitter blade life. By keeping your blades sharp, you save money while also experiencing less downtime and improved product quality. For instance, using high-speed steel or carbide-tipped blades significantly contributes to this goal. These blades can enhance your productivity by making you […]

10 Fatores Chave a Considerar ao Escolher um Fornecedor de Facas de Corte Rotativas

Choosing the right rotary slitter knife supplier can change your cutting results. You need slitting tools that work well and give steady quality. A good supplier with smart manufacturing and helpful service can lower downtime and make your results better. Key Takeaways Blade Quality Standards Precision and Consistency You want slitting knives that work the same every […]

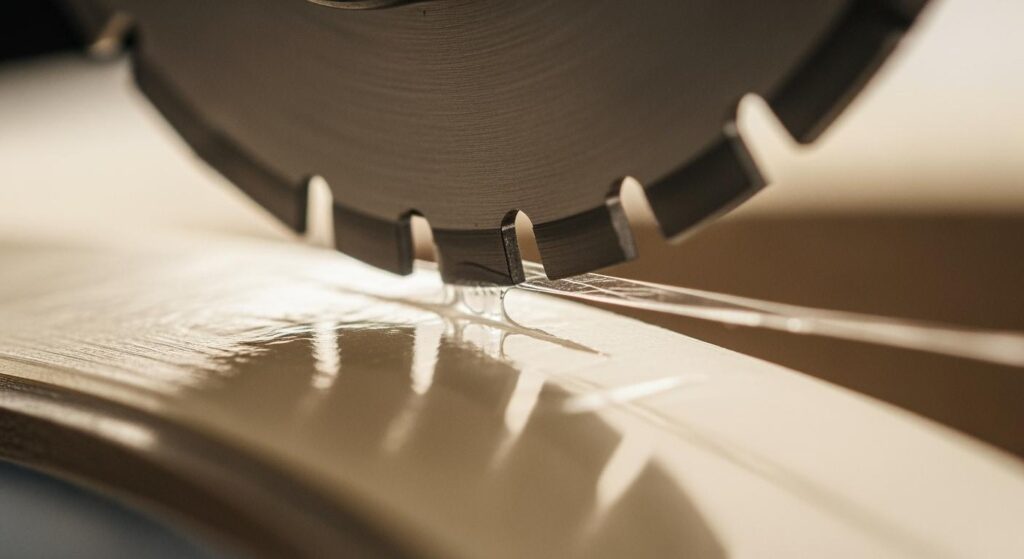

Lâminas de Corte Rotativas para Fita Adesiva: Cortando Através da Aderência do Adesivo

You use rotary slitter blades for tape to cut sticky materials. These blades help you handle tough sticky problems. Sticky problems can slow down how fast you work. If you pick good blades, you get cleaner cuts. Cleaner cuts mean you waste less tape. Blades made from tungsten carbide and high-speed steel last longer. These materials also […]