고부하 페레타이저 블레이드용 CPM vs D2 vs 카바이드 비교 (2026)

High‑load pelletizing punishes cutting edges with abrasive fillers, intermittent impacts, and heat. There’s no universal winner. If edge chipping is your dominant failure mode, CPM tool steels usually outperform conventional D2 and low‑binder carbides. If pure abrasive wear dominates under steady load, cemented carbide can deliver the longest life and most regrinds. Where heat and […]

텅스텐 카바이드 페레타이저 나이프: 최적의 실무 지침서

If abrasive-filled compounds keep chewing through your blades, you’re not alone. Between 0–50% glass fiber, talc/CaCO3 fillers, high line-speed shear, and frequent start/stop cycles, edge life collapses—and pellet quality goes with it. Upgrading to tungsten carbide pelletizer knives addresses the core failure modes while stabilizing pellets and trimming unplanned downtime across strand, die-face/underwater, and ring/centrifugal […]

펠렛 뭉침 방지: 스트랜드 페레타이저 나이프를 위한 최적의 실무 지침

Pellet linking—pellets sticking or fusing together after cutting—wastes time, increases fines, and forces unplanned downtime. In strand pelletizing, the cut must be a clean shear on a fully solidified strand. When knives are dull or mis-set, when runout is present, or when cooling/traction aren’t matched to the polymer, you’ll see smearing, tails, and linked pellets. […]

싼 게 비지떡인 이유: 프리미엄 로터리 슬리터 나이프의 경제학 해독

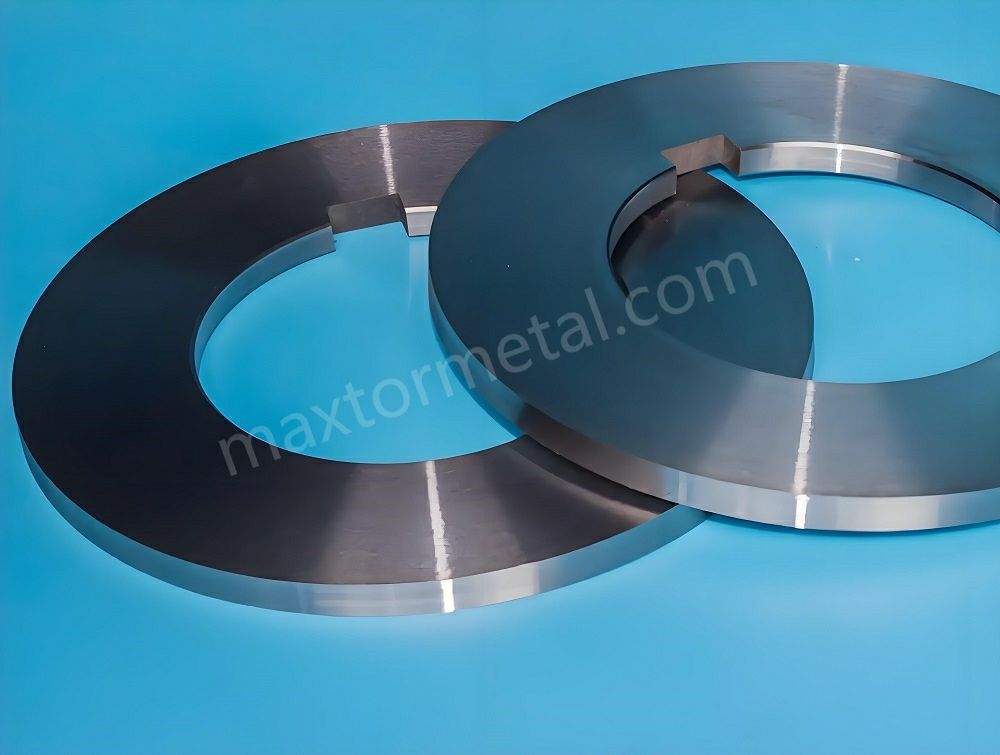

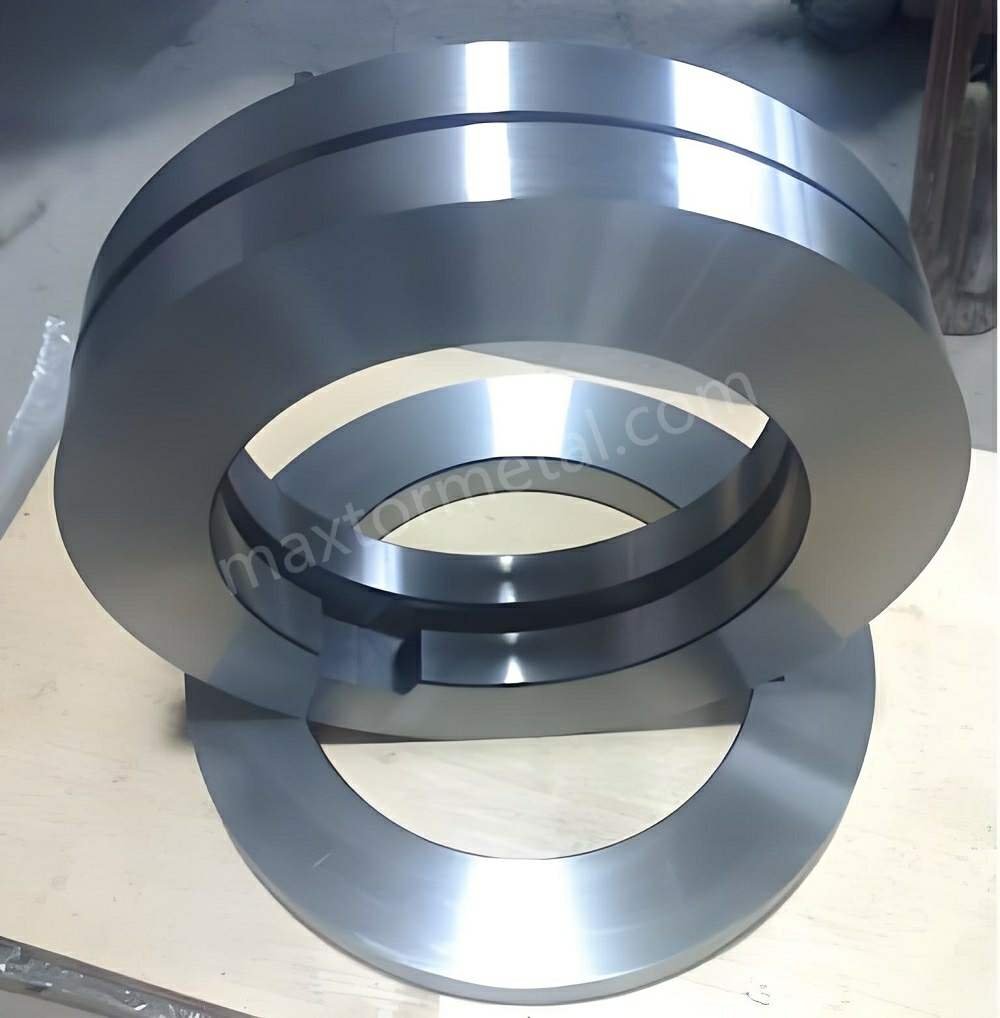

Verdict in 30 seconds: If you’re slitting stainless or high‑strength steels at moderate-to-high speeds—or your downtime costs run above roughly $50,000 per hour—premium Rotary Slitter Knives (HSS/PM‑HSS/Carbide, precision‑ground, coated) win on total cost of ownership. They cut scrap, stretch regrind intervals, and slash changeovers. If you’re a small shop on mild CR/HR steel with downtime […]

AHSS 과제 해결: 자동차용 고장력강을 위한 강철 슬리팅 나이프 선택법

Automotive AHSS grades like DP, TRIP, and martensitic steels can turn a routine slit into a line-stopping headache. Burrs and micro‑chipping surge, edge ductility drops, and downstream formability (HER) suffers. This guide gives plant, process, and maintenance leaders practitioner-grade parameters—material and hardness ranges, coating choices, edge geometry targets, and clearance settings—plus a concise troubleshooting matrix. […]

미러 피니시의 중요성: 장수명을 위한 원형 슬리팅 나이프 제조 방법

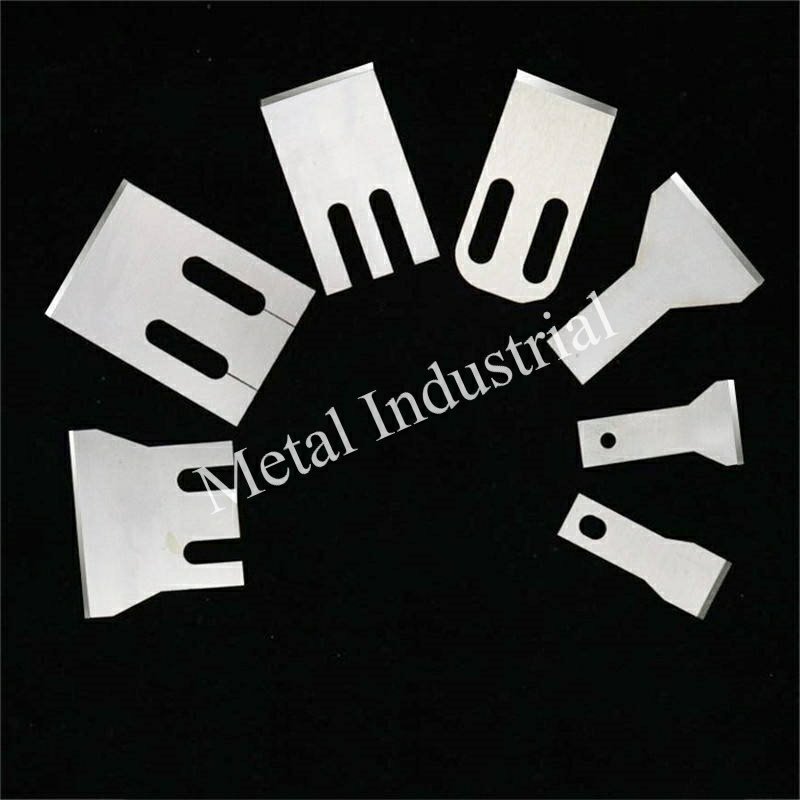

You need a smooth surface to make accurate cuts. A mirror-polished edge on Circular Slitting Knives helps you cut better and faster. This finish stops burrs and friction that slow work. It also keeps material from sticking to the blade. Stuck material can hurt blades and make cuts less exact. Nanjing Metal Industrial makes each blade with great skill. […]

설정 최적화: 완벽한 에지를 위해 슬리팅 라인 나이프와 스페이서가 협력하는 방법

You want each slitting job to have neat, sharp edges. Slitting Line Knives and spacers work as a team. The right material and blade shape help your knives work better. You need to set the space between blades carefully. When you set it up right, you work faster and can use machines to keep the slitting process […]

슬리팅의 과학: 로터리 슬리터 블레이드의 형상이 절단 정밀도에 미치는 영향

You use rotary slitter blades to make accurate and clean cuts. These blades are important in tough manufacturing jobs. The shape of each blade helps you get precise results. It also helps you stop mistakes from happening. Blade material, quality control, and burr reduction all change how accurate your cuts are. They also affect how smooth the finish […]

슬리터 나이프(slitter knives) 최종 가이드: 공차, 재질 및 연마의 이해

Slitter Knife Materials for Steel and More

생산량 극대화: 프리미엄 코일 슬리팅 블레이드가 다운타임을 줄이는 방법

You use Coil Slitting Blades to help your steel service center work well. Premium blades help you have less downtime and cut more steel. Strong materials like tungsten carbide and high-speed steel give you steady, exact cuts. Custom options from brands like Nanjing Metal Industrial help you meet specific needs for your work. Being efficient and exact in cutting […]