Preventing clustered pellets with optimized blade angles

Introduction Clustered pellets—twins, triplets, and fused agglomerates—waste throughput, jam dryers and classifiers, and jeopardize customer quality claims. In underwater and die-face pelletizing, most clustering traces back to pellets leaving the die too hot or tacky, insufficient or unstable quench, or imperfect severance at the die face. Blade geometry sits at the heart of clean severance: […]

How to choose Hot face pelletizing blades for air-cooled PE/PP

Selecting the right hot face pelletizing blades for air-cooled PE/PP isn’t just about material names on a quote. The right choice directly lowers tails and fines, stabilizes cut quality across shifts, and keeps uptime predictable so your total cost of ownership (TCO) tracks to plan. This guide shows you how to specify blade substrate, hardness, […]

Pelletizer Blades that Beat Abrasion in Glass-Fiber Reinforced Resins

Introduction Glass fibers turn an ordinary polyolefin run into an abrasive slurry. Each chopped strand behaves like a microscopic file, accelerating edge rounding on blades and carving faint grooves into the die face. The result? Rising fines and tails, growing vibration, and more frequent blade swaps or regrinds. In die-face/water-ring (underwater) pelletizing of PP/PE with […]

Extending Pelletizer Blade Life: Maintenance Moves that Cut Downtime

By Tommy Tang, Senior Sales Engineer (Nanjing METAL). 12 years supporting pelletizing and size-reduction blade applications. Certifications: CSE, CME, Six Sigma Green Belt, PMP. Scope and validation note: The numeric ranges in this guide are typical starting points used in plant practice. Always follow your OEM manual and site safety rules first, then confirm final setpoints with the […]

How custom pelletizer knives go from CAD to production readiness

Custom pelletizer knives for underwater (water-ring/die-face) cutting don’t become production-ready by chance. They get there through a disciplined chain: CAD intent → DFM reality → controlled manufacturing → auditable QA → run-in validation on your line. In this guide, you’ll see how geometry, materials, precision grinding, and documentation come together to shorten run-in and extend […]

Pellet tails troubleshooting made practical — 5 fixes that work

This guide is for leaders running PE/PP water-ring (die-face hot-cut) pelletizers who need clean pellets, stable throughput, and high uptime. If you’re seeing tails, fines, chaining/doubles, unstable cutting, or noisy contact, use the five fixes below to move fast without guesswork. Quick symptom map: tails (inadequate cooling, dull/misset knives, grooved die face), fines (excessive impact/recirculation, […]

Cut tailing and fines with PVD coated pelletizer knives

Tails and fines are the twin enemies of pellet quality on PE/PP water‑ring (die‑face hot‑cut) lines. Tails start at the die face when the cut isn’t clean—often because of a worn edge, grooved die face, poor alignment, or off‑spec water conditions. Those tails then break off in the dryer, turning into fines and dust that […]

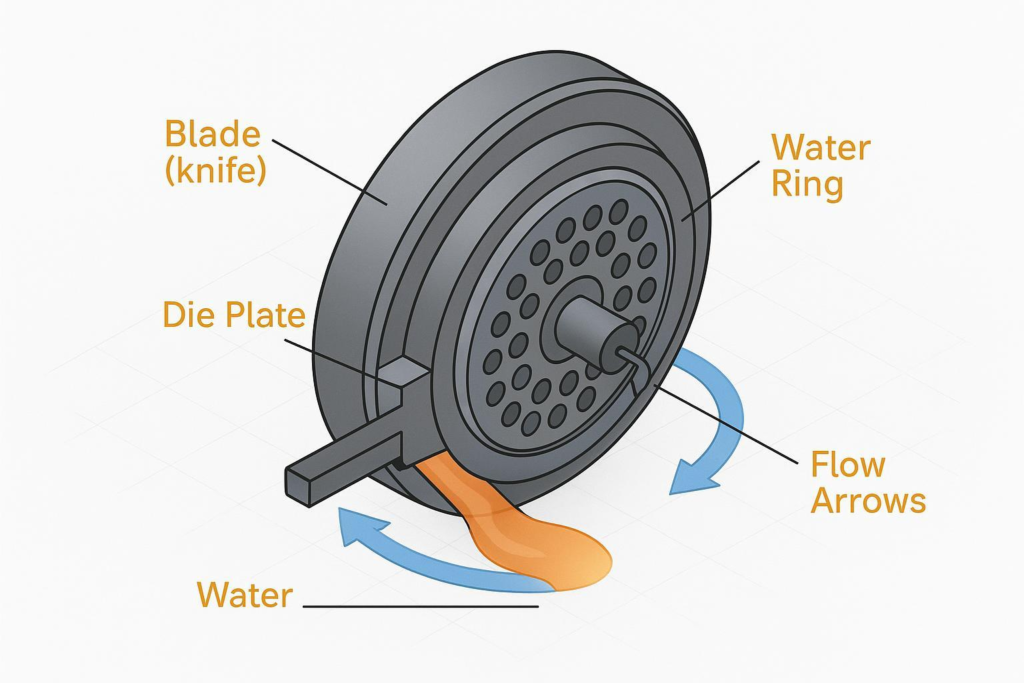

How to choose water ring pelletizer blades for PE/PP lines

Pellet quality, uptime, and total cost per ton decide whether a water-ring (die-face hot-cut) line is truly performing. In PE/PP service, the blade’s material, coating, edge geometry, and dimensional tolerances interact with die-face condition, water-loop stability, and blade speed. Get any of these wrong and you’ll see tails, fines, inconsistent cut length, or avoidable downtime. […]

Best masterbatch pelletizer blades for strand and underwater

Blade selection is one of the fastest levers you can pull to improve pellet uniformity, uptime, and total cost. In strand pelletizing, the blade story is about helical scissor geometry, rotor‑to‑bed knife gap, and how quickly wear drifts that gap. In underwater pelletizing (die‑face/water‑ring), it’s about keeping a clean, stable cut through controlled knife contact […]

Optimizing Pelletizer Blade Sharpness to Achieve Uniform Granule Size

Uniform granule size is not just an aesthetic goal—it drives downstream stability, drying efficiency, metering accuracy, and perceived product quality. The fastest lever you control on the line is blade sharpness, but it only delivers consistent results when it’s linked to the right process window: line speed, cutter RPM, cooling, and die-face conditions. This guide […]