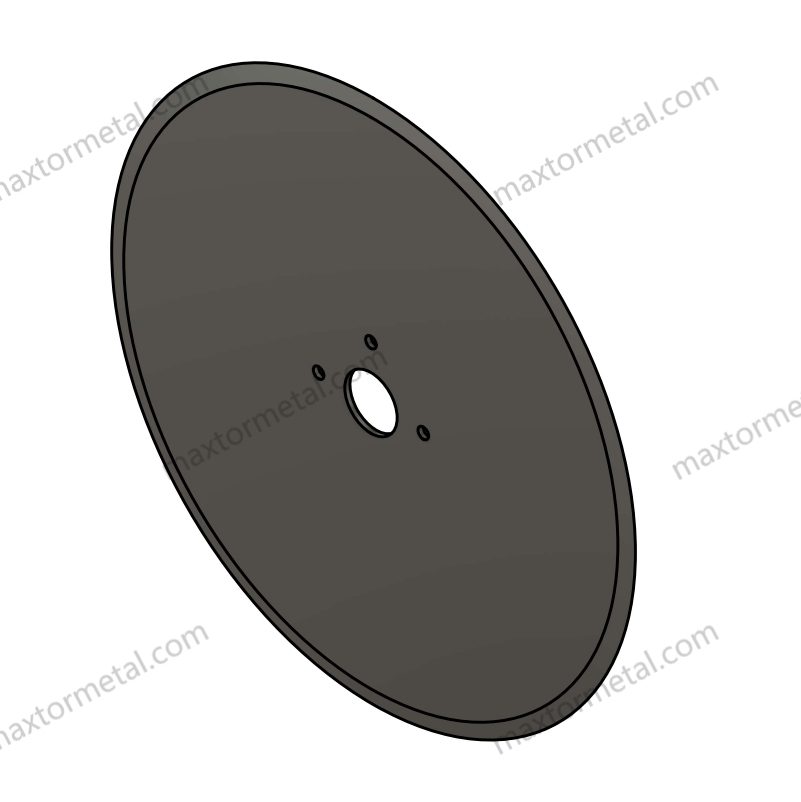

Beseitigung von Kantenstegen: Ein Leitfaden zur Fehlerbehebung für industrielle Metall-Längsteilmesser

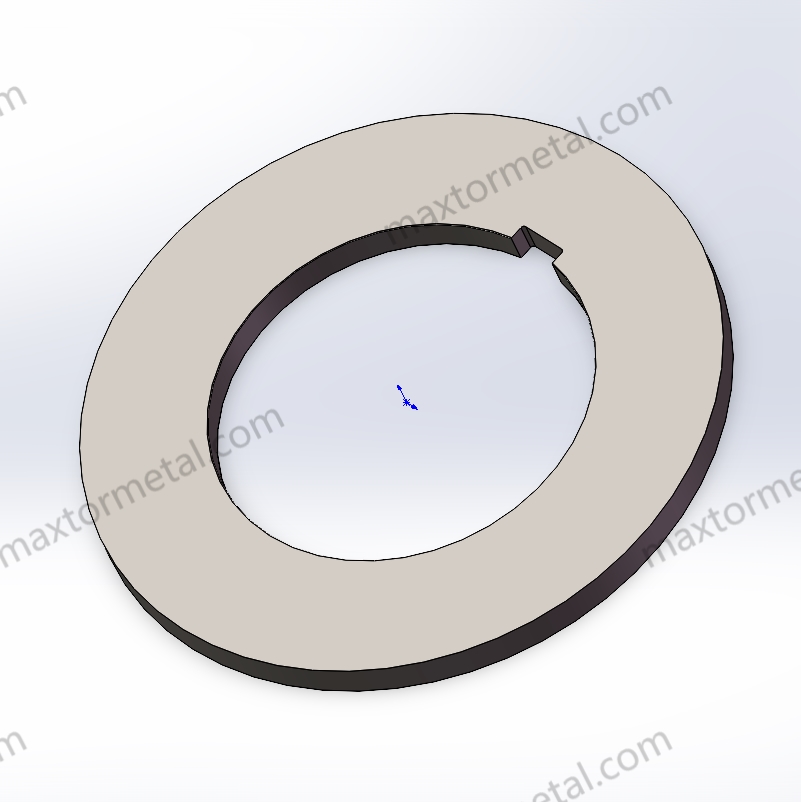

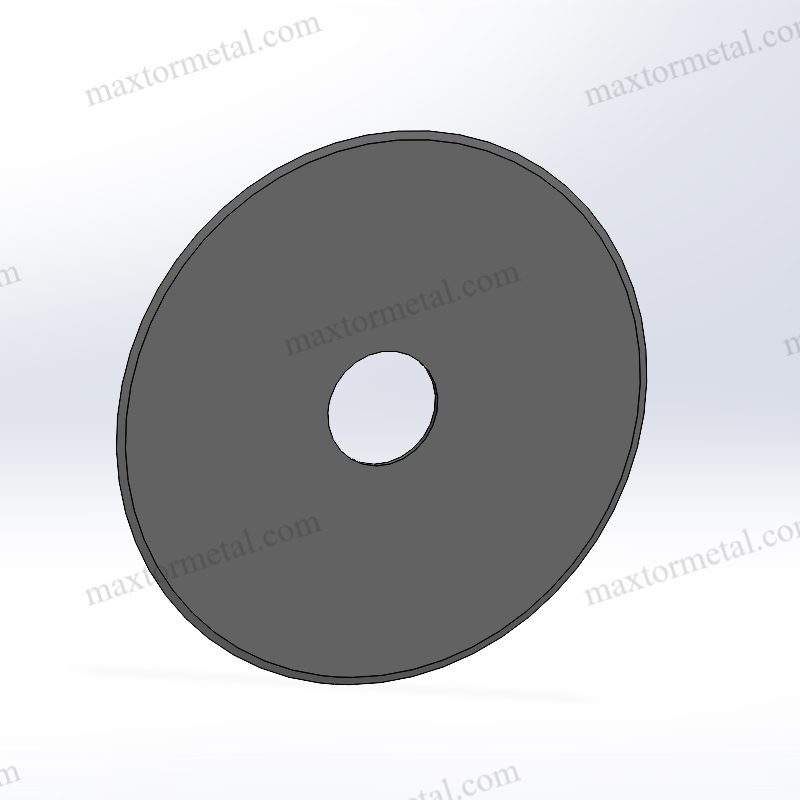

You can lower edge burrs by picking good blades and using good care. Nanjing Metal Industrial’s Roller Shearing Blades use top materials. This helps the cutting edges stay sharp and strong. These blades give you cleaner cuts. You will see fewer rough edges on your metal slitting knives. You can also ask for special blade designs for your […]

So vermeiden Sie Kratzer und Verunreinigungen bei Rollen-Scherenmessern aus Edelstahl

You need to keep stainless steel roller shear blades clean. Do not let them get scratched or dirty. This helps the blades work well and keeps products good. Some things can make the blades dirty: If you do not take care of the blades, big problems can happen. The table below shows some risks and what they can do: […]

So beurteilen Sie die Qualität von Hartmetallklingen anhand von Aussehen und Parametern

Für Ihre Arbeit benötigen Sie hochwertige Sägeblätter. Gute Sägeblätter ermöglichen präzise Schnitte und haben eine längere Lebensdauer. Achten Sie bei der Qualitätskontrolle von Hartmetall-Sägeblättern auf das Aussehen und einige wichtige Details. Beschichtungen wie TiAlN können die Lebensdauer des Sägeblatts verdoppeln. Die richtige Schnittgeschwindigkeit, Schnitttiefe und der richtige Vorschub tragen ebenfalls zur Langlebigkeit Ihres Sägeblatts bei.

Wie PVD-beschichtetes Hartmetall die Lebensdauer der Klinge verdoppelt

PVD coated carbide blades last twice as long. They resist wearing out, have less friction, and stay stable in heat. Many industries use them, like packaging, FPCB, chemical fiber, textiles, food slicing, metal slitting, metalworking, and automotive. TiAlN coatings make tools last over 100% longer than tools without coatings. Many companies, from aerospace to automotive, say their blades […]

Die Schlüsselrolle von Hartmetall-Rasierklingen in der Faser- und Leiterplattenherstellung

You have hard jobs in fiber and PCB manufacturing. You need things to be exact and strong every day. Carbide razor blades help you make smooth cuts and work fast. Tungsten carbide is very hard and lasts a long time. Look at how it matches up with other materials: Material Mohs Hardness Vickers Hardness (Hv) Tungsten Carbide […]

Leitfaden zur Wartung und Optimierung von Wolframkarbid-Klingen

Taking good care of your tungsten carbide blade is essential for optimal performance and longevity. Proper tungsten carbide blade maintenance helps the blade last longer and work better. Tungsten carbide blades from Nanjig Metal Industrial stay sharp longer than steel blades, allowing you to save money over time. Many industries, including automotive, food processing, and metalworking, rely […]

Warum ein höherer Hartmetallklingen-Preis Ihnen Geld spart

Sie möchten wirklich Geld sparen, nicht nur weniger bezahlen. Höhere Preise für Hartmetall-Sägeblätter bedeuten längere Lebensdauer und höhere Arbeitsgeschwindigkeit. Außerdem helfen sie Ihnen, versteckte Kosten zu vermeiden. Viele denken, günstigere Sägeblätter seien günstiger. Doch diese müssen häufiger ausgetauscht werden. Zusätzliche Ausfallzeiten verschwenden Ihre Ressourcen. Achten Sie auf die Kosten pro Schnitt und die Gesamtkosten […]

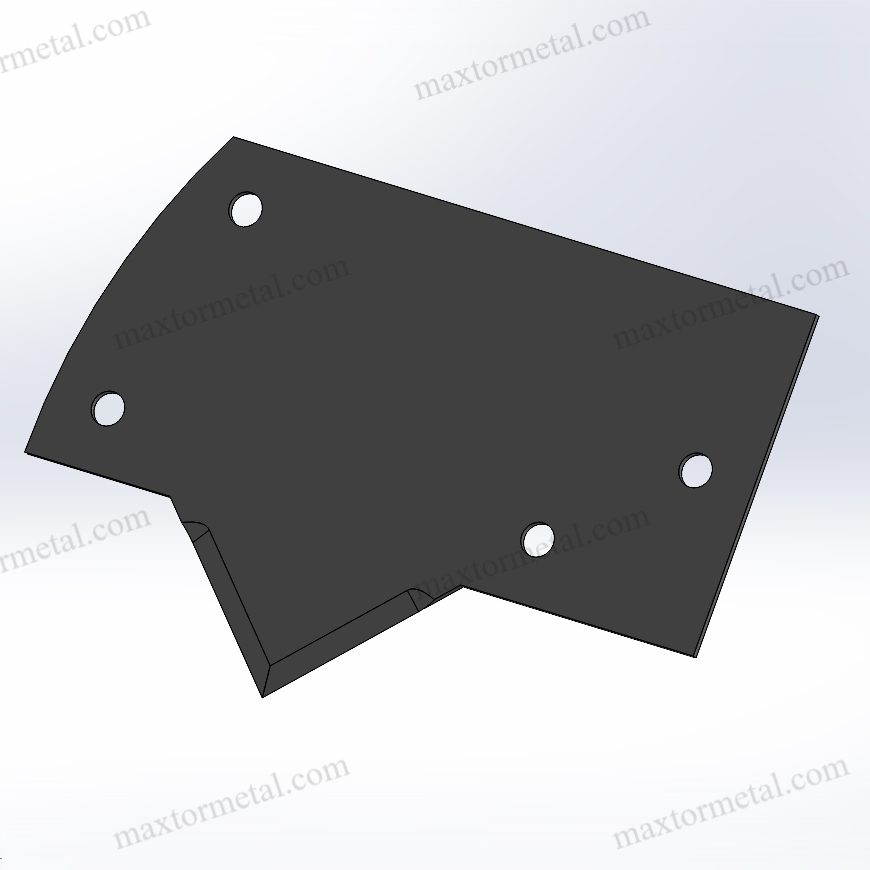

So wählen Sie die besten Hartmetall-Schlitzmesser für Wellpappenanlagen aus

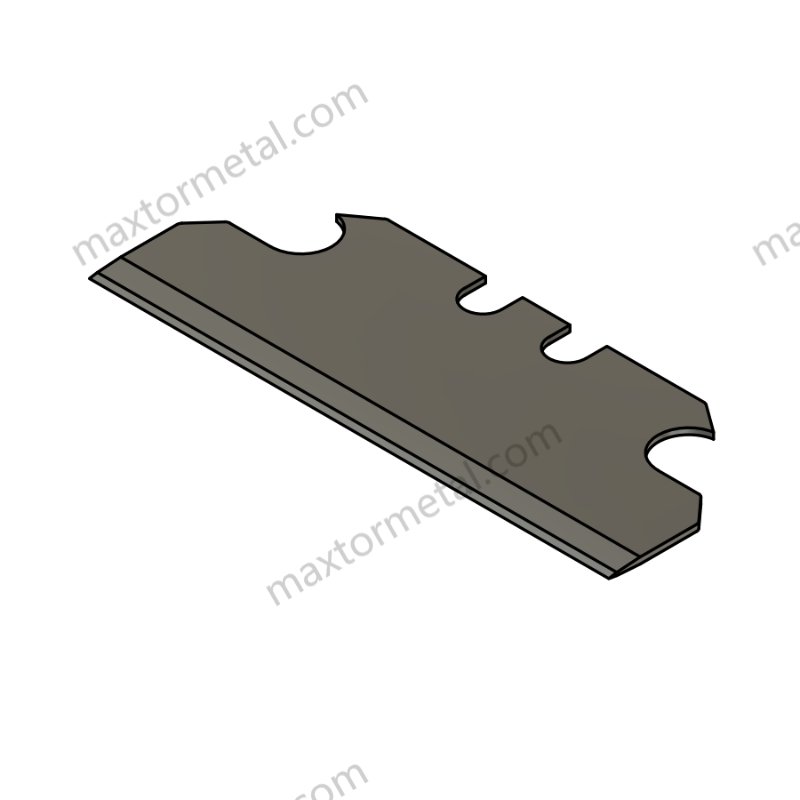

You want each cut from your corrugator to look neat. The right carbide slitting knives help you do this. Tungsten carbide is very hard and does not wear out fast. You change blades less often and have less machine stoppage with these knives. The first price may seem high, but you save money later because the blades […]

Wolframkarbid vs. HSS – Was ist die beste Wahl für Ihre Aufgabe?

When you look at tungsten carbide vs hss, you see that most fast, rough, or careful jobs work better with tungsten carbide. Many industries pick carbide tools because they give: Nanjing Metal Industrial makes tungsten carbide blades that last longer and cut quicker than regular hss blades. The table below shows the main benefits: Advantage Tungsten […]

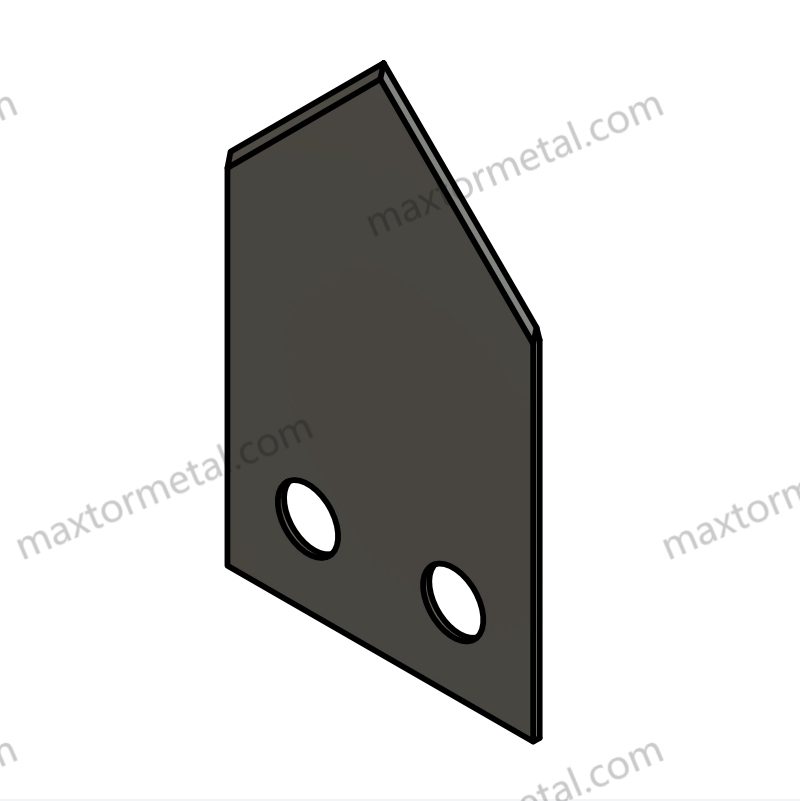

Design von kundenspezifischen Hartmetallklingen für Präzisionsindustrien

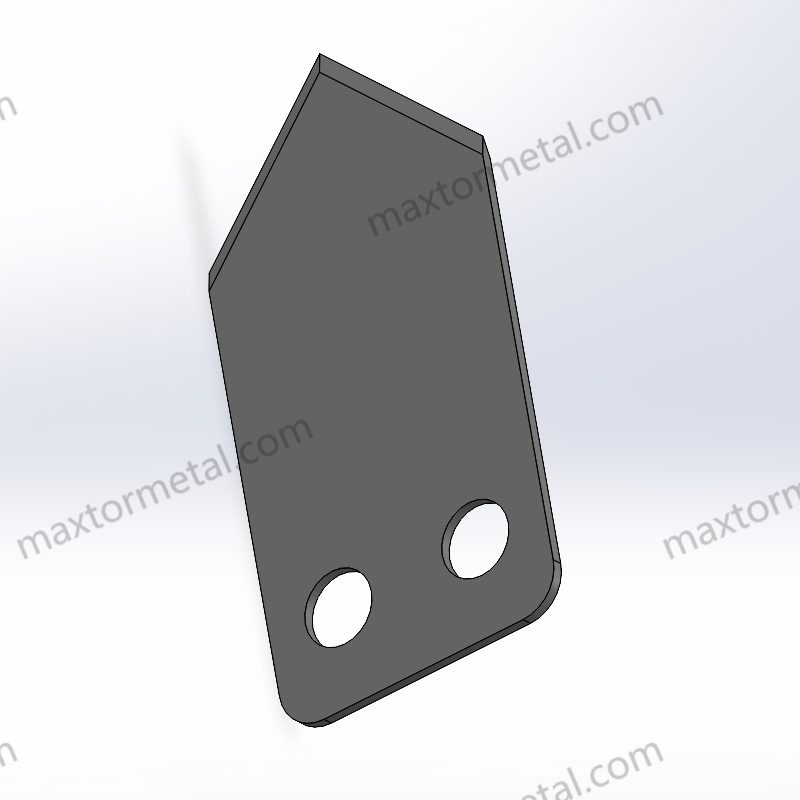

You should think about blade design that fits your cutting needs. It should also solve problems like tool wear and heat. Some materials have special issues too. Custom Carbide Blades help with these problems. They are strong and cut very well. Tungsten carbide blades from Nanjig Metal Industrial last a long time. They help you change tools […]