Druckeinstellung der Granuliermesser und Schutz der Lochplatte

If your underwater pelletizer throws tails, fines, or intermittent leaks, the fix often starts at the knife–die interface. This guide gives operators and engineers a stepwise playbook for pelletizer blade pressure adjustment and die protection across startup, steady long runs, abrasive formulations, and extreme MFI conditions—so you can reduce die wear, extend time between leak […]

Warum CPM-Granuliermesser ideal für hochbelastete Materialien sind

When pelletizing gets tough—abrasive fillers, intermittent impacts, wet chambers, and heat spikes—the wrong pelletizer blade turns your line into a downtime machine. In this context, CPM refers to Crucible Particle Metallurgy, a powder‑metallurgy route that produces fine, uniformly distributed carbides for excellent wear resistance and reliable toughness. Note: CPM is also the well‑known California Pellet […]

CPM vs. D2 vs. Hartmetall für hochbelastete Granuliermesser (2026)

High‑load pelletizing punishes cutting edges with abrasive fillers, intermittent impacts, and heat. There’s no universal winner. If edge chipping is your dominant failure mode, CPM tool steels usually outperform conventional D2 and low‑binder carbides. If pure abrasive wear dominates under steady load, cemented carbide can deliver the longest life and most regrinds. Where heat and […]

Wolframkarbid-Granuliermesser: Best-Practice-Leitfaden

If abrasive-filled compounds keep chewing through your blades, you’re not alone. Between 0–50% glass fiber, talc/CaCO3 fillers, high line-speed shear, and frequent start/stop cycles, edge life collapses—and pellet quality goes with it. Upgrading to tungsten carbide pelletizer knives addresses the core failure modes while stabilizing pellets and trimming unplanned downtime across strand, die-face/underwater, and ring/centrifugal […]

Pellets-Verklebung stoppen: Best Practices für Stranggranulator-Messer

Pellet linking—pellets sticking or fusing together after cutting—wastes time, increases fines, and forces unplanned downtime. In strand pelletizing, the cut must be a clean shear on a fully solidified strand. When knives are dull or mis-set, when runout is present, or when cooling/traction aren’t matched to the polymer, you’ll see smearing, tails, and linked pellets. […]

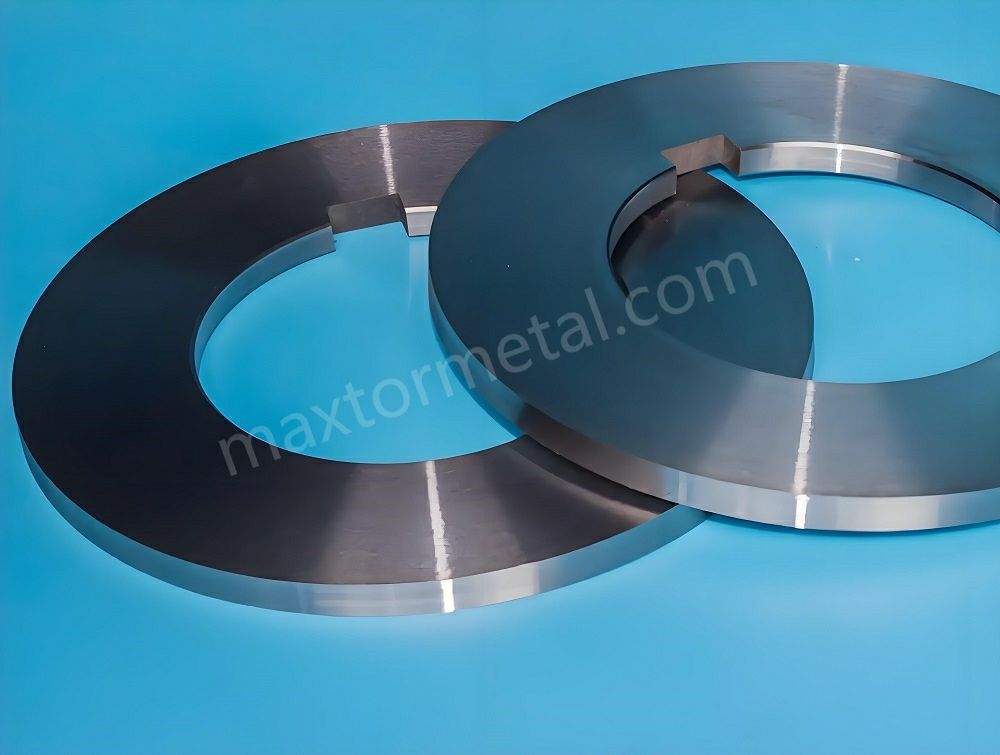

Warum billig teuer ist: Die Ökonomie erstklassiger Rundmesser entschlüsselt

Verdict in 30 seconds: If you’re slitting stainless or high‑strength steels at moderate-to-high speeds—or your downtime costs run above roughly $50,000 per hour—premium Rotary Slitter Knives (HSS/PM‑HSS/Carbide, precision‑ground, coated) win on total cost of ownership. They cut scrap, stretch regrind intervals, and slash changeovers. If you’re a small shop on mild CR/HR steel with downtime […]

AHSS-Herausforderungen meistern: Auswahl von Stahllängsteilmesser für hochfesten Automobilstahl

Automotive AHSS grades like DP, TRIP, and martensitic steels can turn a routine slit into a line-stopping headache. Burrs and micro‑chipping surge, edge ductility drops, and downstream formability (HER) suffers. This guide gives plant, process, and maintenance leaders practitioner-grade parameters—material and hardness ranges, coating choices, edge geometry targets, and clearance settings—plus a concise troubleshooting matrix. […]

Die Bedeutung des Spiegel-Finishs: Wie Rundmesser für eine lange Lebensdauer hergestellt werden

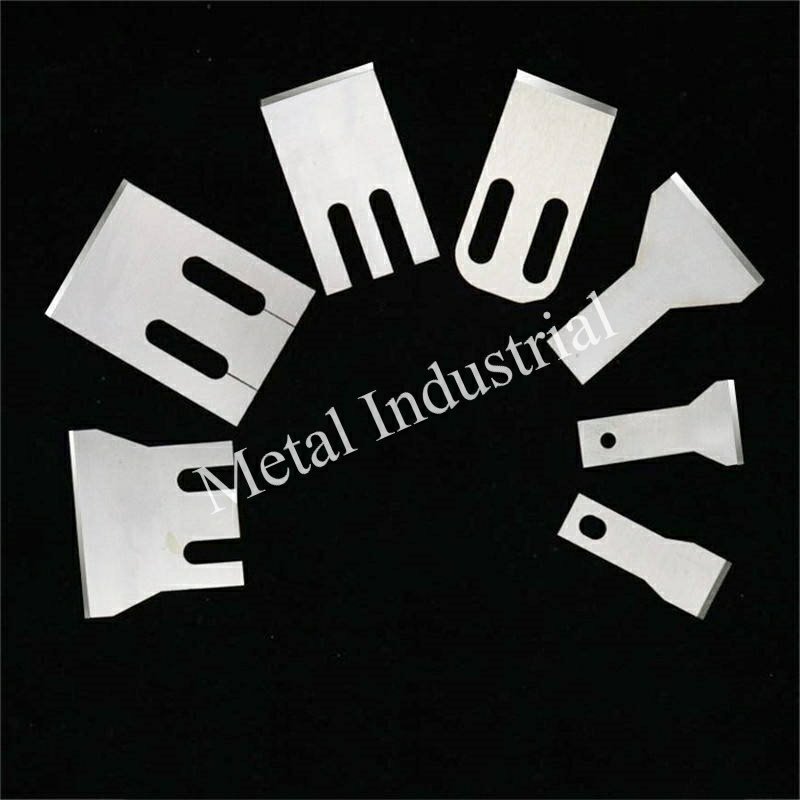

You need a smooth surface to make accurate cuts. A mirror-polished edge on Circular Slitting Knives helps you cut better and faster. This finish stops burrs and friction that slow work. It also keeps material from sticking to the blade. Stuck material can hurt blades and make cuts less exact. Nanjing Metal Industrial makes each blade with great skill. […]

Optimierung Ihres Setups: Wie Längsteilanlagen-Messer und Zwischenringe für perfekte Kanten zusammenwirken

You want each slitting job to have neat, sharp edges. Slitting Line Knives and spacers work as a team. The right material and blade shape help your knives work better. You need to set the space between blades carefully. When you set it up right, you work faster and can use machines to keep the slitting process […]

Die Wissenschaft des Längsteilens: Wie die Geometrie von Rundmessern Ihre Schnittpräzision beeinflusst

You use rotary slitter blades to make accurate and clean cuts. These blades are important in tough manufacturing jobs. The shape of each blade helps you get precise results. It also helps you stop mistakes from happening. Blade material, quality control, and burr reduction all change how accurate your cuts are. They also affect how smooth the finish […]