Comment les couteaux de granulateur sur mesure passent de la CAO à la production

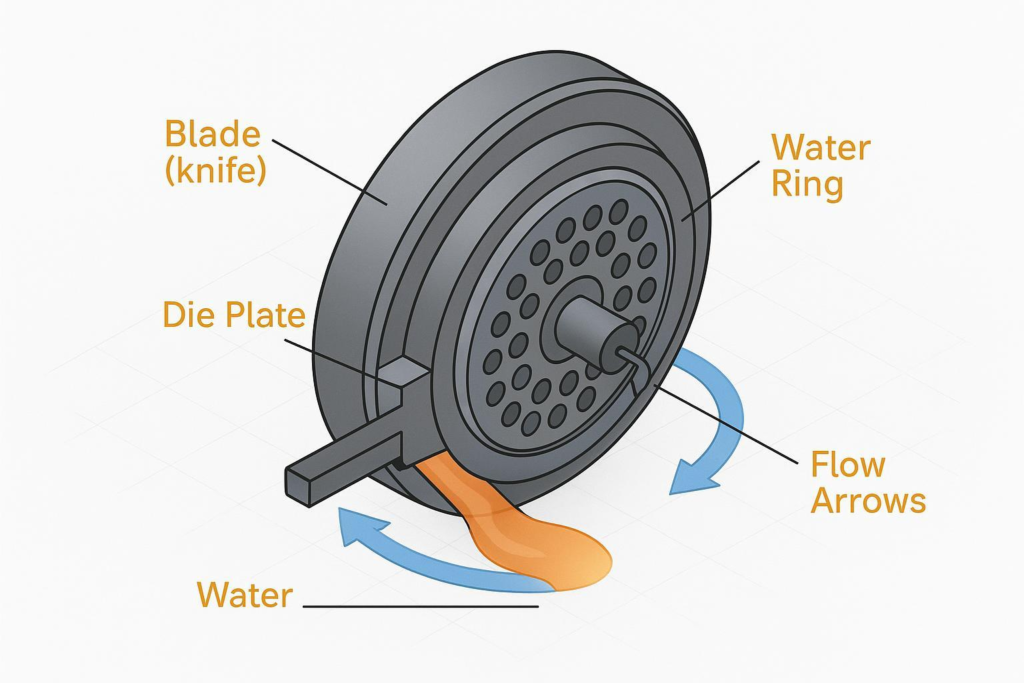

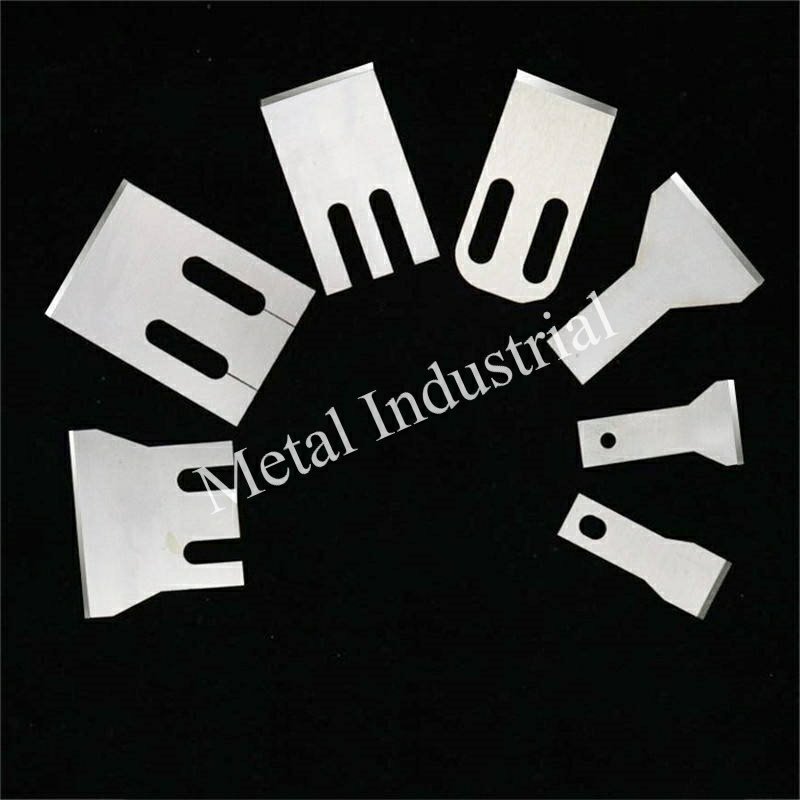

Custom pelletizer knives for underwater (water-ring/die-face) cutting don’t become production-ready by chance. They get there through a disciplined chain: CAD intent → DFM reality → controlled manufacturing → auditable QA → run-in validation on your line. In this guide, you’ll see how geometry, materials, precision grinding, and documentation come together to shorten run-in and extend […]

Dépannage des queues de granulés : 5 solutions pratiques et efficaces

This guide is for leaders running PE/PP water-ring (die-face hot-cut) pelletizers who need clean pellets, stable throughput, and high uptime. If you’re seeing tails, fines, chaining/doubles, unstable cutting, or noisy contact, use the five fixes below to move fast without guesswork. Quick symptom map: tails (inadequate cooling, dull/misset knives, grooved die face), fines (excessive impact/recirculation, […]

Réduisez les queues et les fines avec les couteaux de granulateur à revêtement PVD

Tails and fines are the twin enemies of pellet quality on PE/PP water‑ring (die‑face hot‑cut) lines. Tails start at the die face when the cut isn’t clean—often because of a worn edge, grooved die face, poor alignment, or off‑spec water conditions. Those tails then break off in the dryer, turning into fines and dust that […]

Comment choisir les couteaux de granulateur à anneau d'eau pour les lignes PE/PP

Pellet quality, uptime, and total cost per ton decide whether a water-ring (die-face hot-cut) line is truly performing. In PE/PP service, the blade’s material, coating, edge geometry, and dimensional tolerances interact with die-face condition, water-loop stability, and blade speed. Get any of these wrong and you’ll see tails, fines, inconsistent cut length, or avoidable downtime. […]

Les meilleurs couteaux de granulateur de masterbatch pour les systèmes à jonc et sous l'eau

Blade selection is one of the fastest levers you can pull to improve pellet uniformity, uptime, and total cost. In strand pelletizing, the blade story is about helical scissor geometry, rotor‑to‑bed knife gap, and how quickly wear drifts that gap. In underwater pelletizing (die‑face/water‑ring), it’s about keeping a clean, stable cut through controlled knife contact […]

Optimisation du tranchant des couteaux de granulateur pour obtenir une taille de granulés uniforme

Uniform granule size is not just an aesthetic goal—it drives downstream stability, drying efficiency, metering accuracy, and perceived product quality. The fastest lever you control on the line is blade sharpness, but it only delivers consistent results when it’s linked to the right process window: line speed, cutter RPM, cooling, and die-face conditions. This guide […]

Réglage de la pression des couteaux de granulateur et protection de la filière

If your underwater pelletizer throws tails, fines, or intermittent leaks, the fix often starts at the knife–die interface. This guide gives operators and engineers a stepwise playbook for pelletizer blade pressure adjustment and die protection across startup, steady long runs, abrasive formulations, and extreme MFI conditions—so you can reduce die wear, extend time between leak […]

Pourquoi les lames de granulateur CPM sont idéales pour les matériaux à haute charge

When pelletizing gets tough—abrasive fillers, intermittent impacts, wet chambers, and heat spikes—the wrong pelletizer blade turns your line into a downtime machine. In this context, CPM refers to Crucible Particle Metallurgy, a powder‑metallurgy route that produces fine, uniformly distributed carbides for excellent wear resistance and reliable toughness. Note: CPM is also the well‑known California Pellet […]

CPM vs D2 vs Carbure pour les lames de granulateur à haute charge (2026)

Le pelletage à charge élevée soumet les arêtes de coupe à rude épreuve grâce à des charges abrasives, des impacts intermittents et la chaleur. Il n'existe pas de solution universelle. Si l'écaillage des arêtes est le principal mode de défaillance, les aciers à outils CPM sont généralement plus performants que les aciers D2 conventionnels et les carbures à faible liant. Si l'usure abrasive pure prédomine sous charge constante, le carbure cémenté offre la durée de vie la plus longue et le plus grand nombre de réaffûtages. Lorsque la chaleur et […]

Couteaux de granulateur en carbure de tungstène : Guide des meilleures pratiques

Si les composés abrasifs usent prématurément vos lames, vous n'êtes pas seul. Entre les fibres de verre 0-50%, les charges de talc/CaCO3, le cisaillement à haute vitesse et les cycles d'arrêt/démarrage fréquents, la durée de vie des lames chute drastiquement, entraînant une baisse de la qualité des granulés. Le passage à des lames de granulateur en carbure de tungstène permet de résoudre les principaux problèmes de défaillance, tout en stabilisant les granulés et en réduisant les temps d'arrêt imprévus sur les lignes de production, les filières/la zone de granulation sous-marine et les systèmes de granulation par centrifugation.