Come scegliere le lame per granulazione a caldo per PE/PP raffreddato ad aria

Selecting the right hot face pelletizing blades for air-cooled PE/PP isn’t just about material names on a quote. The right choice directly lowers tails and fines, stabilizes cut quality across shifts, and keeps uptime predictable so your total cost of ownership (TCO) tracks to plan. This guide shows you how to specify blade substrate, hardness, […]

Lame per granulatori che battono l'abrasione nelle resine rinforzate con fibra di vetro

Introduction Glass fibers turn an ordinary polyolefin run into an abrasive slurry. Each chopped strand behaves like a microscopic file, accelerating edge rounding on blades and carving faint grooves into the die face. The result? Rising fines and tails, growing vibration, and more frequent blade swaps or regrinds. In die-face/water-ring (underwater) pelletizing of PP/PE with […]

Prolungare la durata delle lame del granulatore: interventi di manutenzione per ridurre i tempi di fermo

By Tommy Tang, Senior Sales Engineer (Nanjing METAL). 12 years supporting pelletizing and size-reduction blade applications. Certifications: CSE, CME, Six Sigma Green Belt, PMP. Scope and validation note: The numeric ranges in this guide are typical starting points used in plant practice. Always follow your OEM manual and site safety rules first, then confirm final setpoints with the […]

Come le lame per granulatori personalizzate passano dal CAD alla produzione

Custom pelletizer knives for underwater (water-ring/die-face) cutting don’t become production-ready by chance. They get there through a disciplined chain: CAD intent → DFM reality → controlled manufacturing → auditable QA → run-in validation on your line. In this guide, you’ll see how geometry, materials, precision grinding, and documentation come together to shorten run-in and extend […]

Risoluzione dei problemi delle "code" nei granuli (Pellet Tails): 5 soluzioni pratiche e collaudate

This guide is for leaders running PE/PP water-ring (die-face hot-cut) pelletizers who need clean pellets, stable throughput, and high uptime. If you’re seeing tails, fines, chaining/doubles, unstable cutting, or noisy contact, use the five fixes below to move fast without guesswork. Quick symptom map: tails (inadequate cooling, dull/misset knives, grooved die face), fines (excessive impact/recirculation, […]

Riduci code e fini con le lame per granulatori con rivestimento PVD

Tails and fines are the twin enemies of pellet quality on PE/PP water‑ring (die‑face hot‑cut) lines. Tails start at the die face when the cut isn’t clean—often because of a worn edge, grooved die face, poor alignment, or off‑spec water conditions. Those tails then break off in the dryer, turning into fines and dust that […]

Come scegliere le lame per granulatori ad anello d'acqua per linee PE/PP

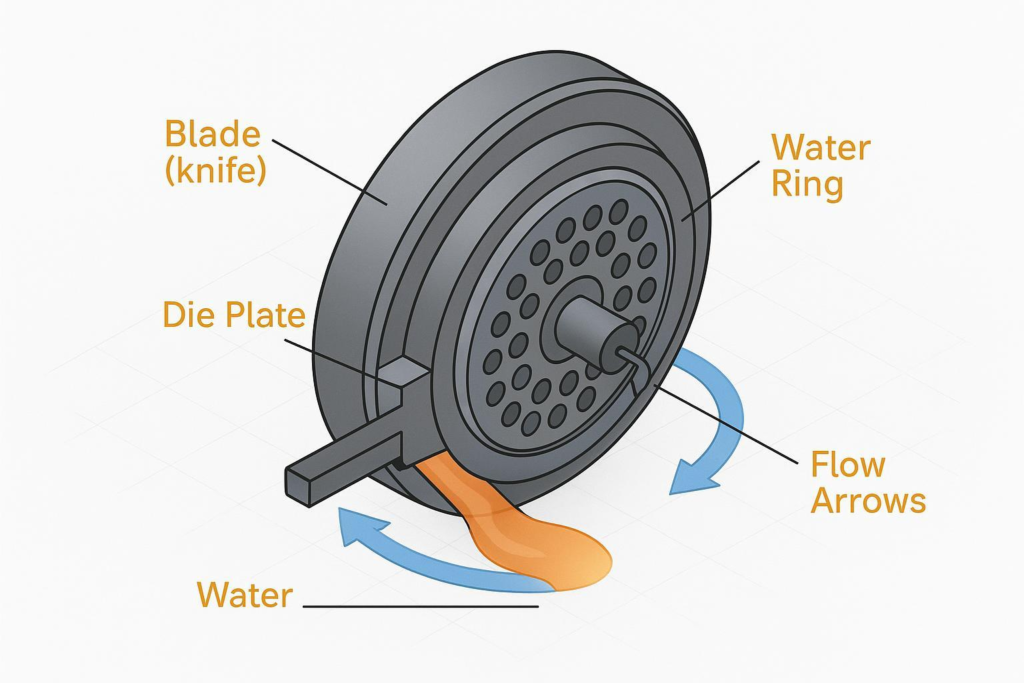

Pellet quality, uptime, and total cost per ton decide whether a water-ring (die-face hot-cut) line is truly performing. In PE/PP service, the blade’s material, coating, edge geometry, and dimensional tolerances interact with die-face condition, water-loop stability, and blade speed. Get any of these wrong and you’ll see tails, fines, inconsistent cut length, or avoidable downtime. […]

Le migliori lame per granulatori di masterbatch per sistemi a filo e sott'acqua

La selezione della lama è uno degli strumenti più rapidi per migliorare l'uniformità del pellet, i tempi di attività e i costi totali. Nella pellettizzazione a filamento, la questione della lama riguarda la geometria elicoidale delle forbici, la distanza tra rotore e base della lama e la rapidità con cui l'usura sposta tale distanza. Nella pellettizzazione subacquea (trafila/anello ad acqua), si tratta di mantenere un taglio pulito e stabile attraverso il contatto controllato della lama […]

Ottimizzazione dell'affilatezza delle lame del granulatore per ottenere una dimensione uniforme dei granuli

Uniform granule size is not just an aesthetic goal—it drives downstream stability, drying efficiency, metering accuracy, and perceived product quality. The fastest lever you control on the line is blade sharpness, but it only delivers consistent results when it’s linked to the right process window: line speed, cutter RPM, cooling, and die-face conditions. This guide […]

Regolazione della pressione delle lame del granulatore e protezione della filiera

If your underwater pelletizer throws tails, fines, or intermittent leaks, the fix often starts at the knife–die interface. This guide gives operators and engineers a stepwise playbook for pelletizer blade pressure adjustment and die protection across startup, steady long runs, abrasive formulations, and extreme MFI conditions—so you can reduce die wear, extend time between leak […]