高負荷ペレタイザー刃の材質比較:CPM vs D2 vs 超硬 (2026)

High‑load pelletizing punishes cutting edges with abrasive fillers, intermittent impacts, and heat. There’s no universal winner. If edge chipping is your dominant failure mode, CPM tool steels usually outperform conventional D2 and low‑binder carbides. If pure abrasive wear dominates under steady load, cemented carbide can deliver the longest life and most regrinds. Where heat and thermal softening creep in, CPM M4 or hot‑work steels paired with heat‑resistant coatings make a real difference. Key takeaways Side‑by‑side comparison (indicative — consult datasheets for exact values) Best‑for scenario Material family & example grades Microstructure highlights Typical hardness window Edge chipping resistance Abrasive wear resistance Hot hardness / temper resistance Plastic deformation resistance Regrind […]

超硬合金(タングステンカーバイド)製ペレタイザーナイフ:ベストプラクティスガイド

If abrasive-filled compounds keep chewing through your blades, you’re not alone. Between 0–50% glass fiber, talc/CaCO3 fillers, high line-speed shear, and frequent start/stop cycles, edge life collapses—and pellet quality goes with it. Upgrading to tungsten carbide pelletizer knives addresses the core failure modes while stabilizing pellets and trimming unplanned downtime across strand, die-face/underwater, and ring/centrifugal systems. Key takeaways Why Tungsten carbide pelletizer knives matter: the wear you’re really fighting Abrasive mineral fillers (talc, CaCO3) and glass fiber ends act like sandpaper at the cutting interface. At high line speeds, the edge sees three-body abrasion that rounds the cutting radius and elevates fines. Frequent start/stop increases impact loading and thermal cycling, […]

ペレットの連なりを防ぐ:ストランドペレタイザー用ナイフのベストプラクティス

Pellet linking—pellets sticking or fusing together after cutting—wastes time, increases fines, and forces unplanned downtime. In strand pelletizing, the cut must be a clean shear on a fully solidified strand. When knives are dull or mis-set, when runout is present, or when cooling/traction aren’t matched to the polymer, you’ll see smearing, tails, and linked pellets. This guide consolidates field-proven troubleshooting steps, setup ranges, and knife geometry/materials guidance so you can fix linking fast and keep lines stable. Key Takeaways Strand Pelletizer Knives: A Step-by-Step Troubleshooting Workflow Pellet linking has multiple interacting causes. Work the checks in order and document adjustments to your strand pelletizer knives setup. Safety and Symptom Logging […]

「安物買いの銭失い」の理由:プレミアムなロータリースリッターナイフの経済性を解明

Verdict in 30 seconds: If you’re slitting stainless or high‑strength steels at moderate-to-high speeds—or your downtime costs run above roughly $50,000 per hour—premium Rotary Slitter Knives (HSS/PM‑HSS/Carbide, precision‑ground, coated) win on total cost of ownership. They cut scrap, stretch regrind intervals, and slash changeovers. If you’re a small shop on mild CR/HR steel with downtime under ~$10,000 per hour and conservative speeds, budget D2 or basic HSS can still be the economical choice. Our math anchors on three numbers: A) unplanned downtime $/h, B) total cost per changeover/regrind, and C) savings per 1% scrap‑rate reduction. Key takeaways Cheap vs premium Rotary Slitter Knives: the fast comparison (as of 2026‑01‑20) Below […]

AHSSの課題に挑む:自動車用高張力鋼(ハイテン)向けスリッターナイフの選

Automotive AHSS grades like DP, TRIP, and martensitic steels can turn a routine slit into a line-stopping headache. Burrs and micro‑chipping surge, edge ductility drops, and downstream formability (HER) suffers. This guide gives plant, process, and maintenance leaders practitioner-grade parameters—material and hardness ranges, coating choices, edge geometry targets, and clearance settings—plus a concise troubleshooting matrix. The goal: cleaner edges, fewer defects, and predictable performance when slitting AHSS. Key takeaways Why AHSS changes the rules AHSS combines high tensile strength with multiphase microstructures (martensite in ferrite), which raises cutting forces and amplifies sensitivity to parameter errors. Mechanical cutting reduces edge ductility; minimizing damage in the shear-affected zone is essential for better […]

鏡面仕上げの重要性:長寿命な円形スリッターナイフの製造方法

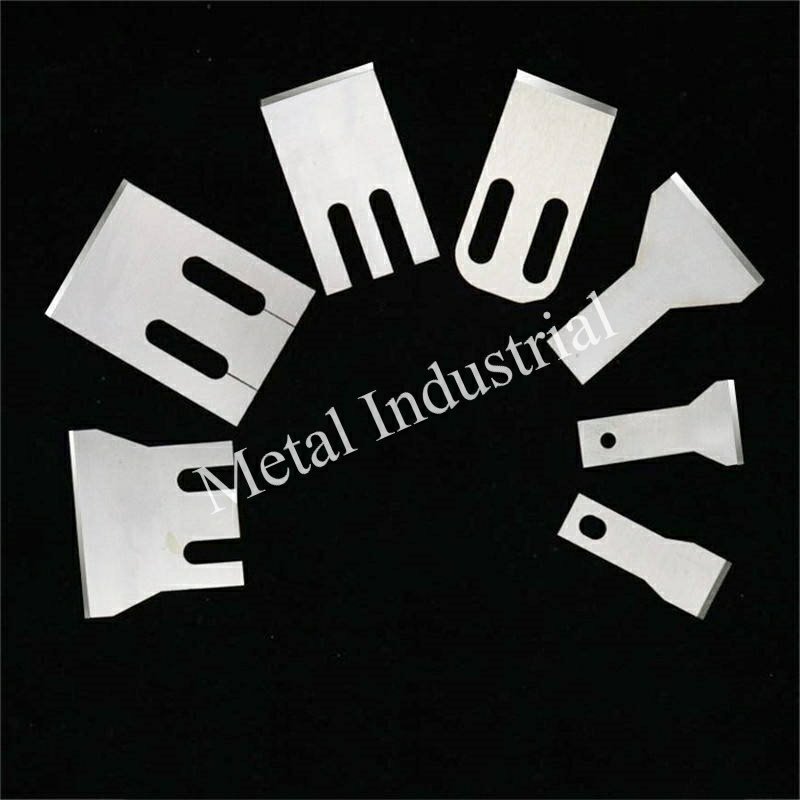

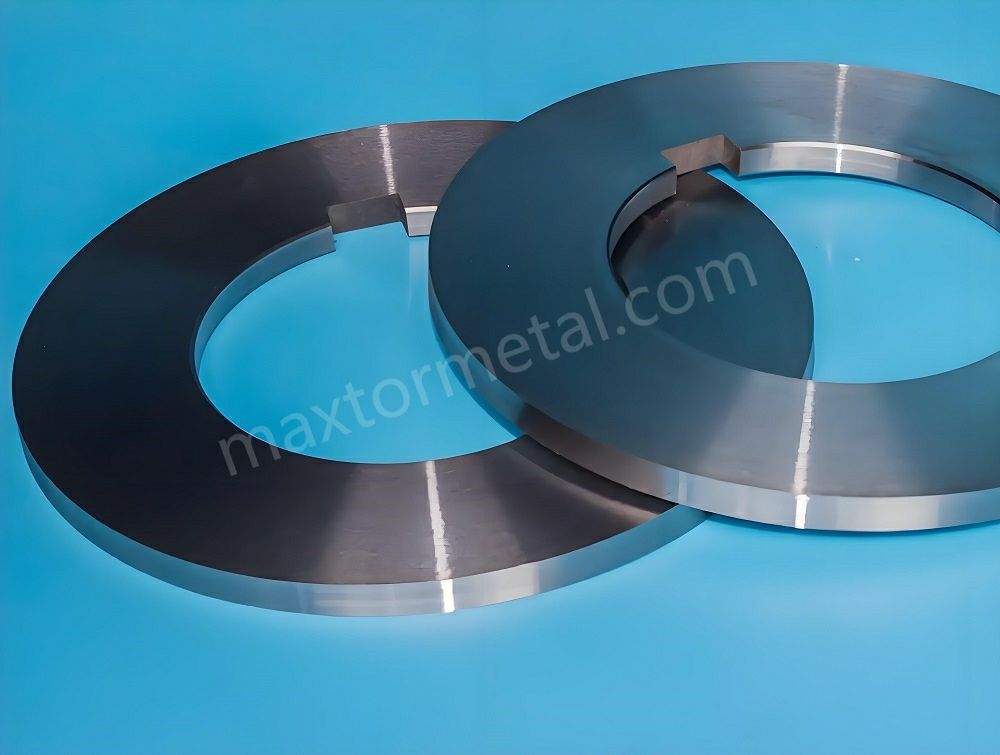

You need a smooth surface to make accurate cuts. A mirror-polished edge on Circular Slitting Knives helps you cut better and faster. This finish stops burrs and friction that slow work. It also keeps material from sticking to the blade. Stuck material can hurt blades and make cuts less exact. Nanjing Metal Industrial makes each blade with great skill. They always give you high quality for tough jobs. Key Takeaways Mirror Finish and Cutting Precision Why Mirror Finish Matters You want your blade to make clean cuts every time. A mirror finish on circular slitting knives helps you do this. The smooth surface makes the blade slide easily over the material. This means there […]

セットアップの最適化:完璧なエッジのためにスリッターラインナイフとスペーサーがどのように連携するか

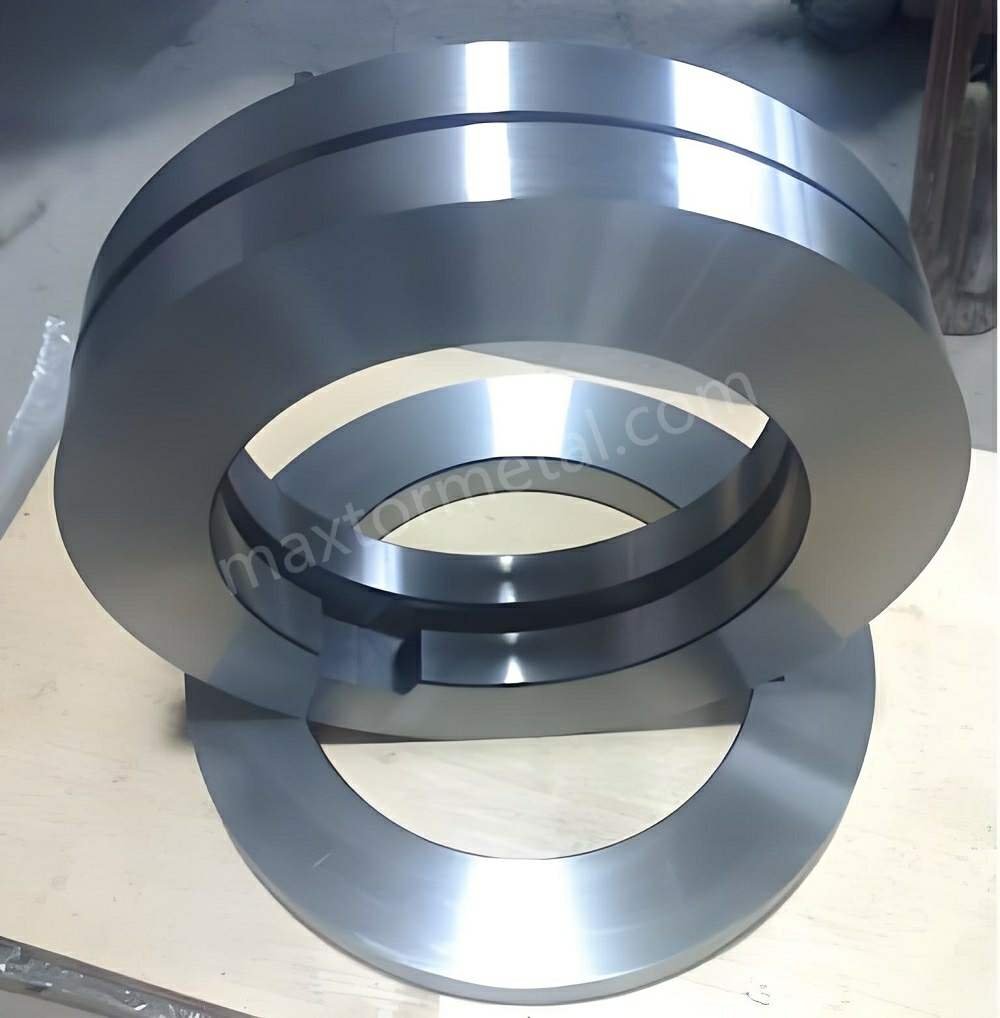

You want each slitting job to have neat, sharp edges. Slitting Line Knives and spacers work as a team. The right material and blade shape help your knives work better. You need to set the space between blades carefully. When you set it up right, you work faster and can use machines to keep the slitting process smooth. Key Takeaways Slitting Line Knives: Role & Features Cutting Function in Slitting Slitting line knives cut big coils of metal into thin strips. First, you put a master coil on the uncoiler. The metal moves through blades set to the right width. Each blade is in the right spot for the strip size you […]

スリッティングの科学:ロータリースリッター刃の形状が切断精度に与える影響

You use rotary slitter blades to make accurate and clean cuts. These blades are important in tough manufacturing jobs. The shape of each blade helps you get precise results. It also helps you stop mistakes from happening. Blade material, quality control, and burr reduction all change how accurate your cuts are. They also affect how smooth the finish looks. Look at how these things compare: Evidence Point Description Blade Material The blade material you pick changes how long it lasts. It also changes how well it cuts and how good the cut looks. Quality Control Strong quality control makes sure every blade is made right. This is very important for keeping your cuts […]

スリッターナイフの究極ガイド:公差、材質、研磨を理解する

Slitter Knife Materials for Steel and More

トン数の最大化:プレミアムなコイル・スリッター刃がダウンタイムを短縮する方法

You use Coil Slitting Blades to help your steel service center work well. Premium blades help you have less downtime and cut more steel. Strong materials like tungsten carbide and high-speed steel give you steady, exact cuts. Custom options from brands like Nanjing Metal Industrial help you meet specific needs for your work. Being efficient and exact in cutting helps you work faster and get good results. Key Takeaways Coil Slitting Blades and Their Impact Role in Steel Service Centers You need coil slitting blades to keep your steel service center working well. These blades cut big coils of steel into smaller strips. You use these strips for many jobs in factories. Picking the […]